Researchers at The University of British Columbia (UBC) in Canada have developed a new environmentally friendly packaging foam to address plastic pollution.

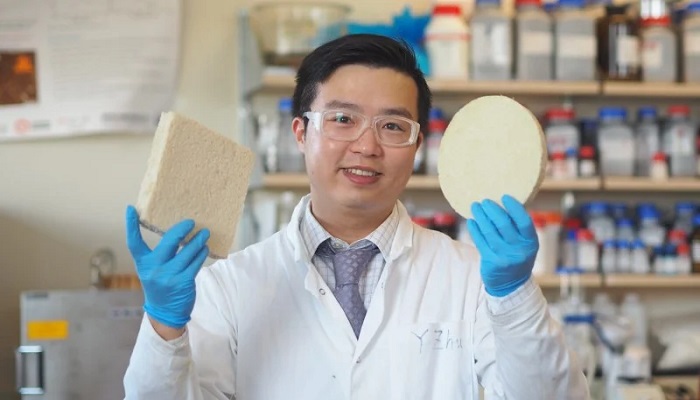

Named BioFoam, the new packaging is the outcome of two years of collaboration between Dr Feng Jiang and postdoctoral fellow Dr Yeling Zhu from UBC and Reg Ogen and Joe Wong, president and CEO and vice-president of Wet’suwet’en First Nation’s Yinka Dene Economic Development Limited Partnership, respectively.

The team also involves the Office of Chief Forester in the Ministry of Forests.iofoam is claimed to degrade in a couple of weeks in the soil and can be used as a sustainable alternative for packaging foams, packing peanuts and thermal insulation boards.

Dr Feng Jiang said: “Styrofoam waste fills up to 30% of global landfills and can take more than 500 years to break down.

“Our biofoam breaks down in the soil in a couple of weeks, requires little heat and few chemicals to make, and can be used as a substitute for packaging foams, packing peanuts and even thermal insulation boards.”

Dr Jiang Jiang started working on Biofoam many years ago with the intention of repurposing wood waste from harvested trees and reducing pollution from packaging foam.

Dr Feng Jiang added: “Less than 50% of harvested trees are used in the wood industries, the rest is left behind in the forest, serving as potential fuel for devastating wildfires.”