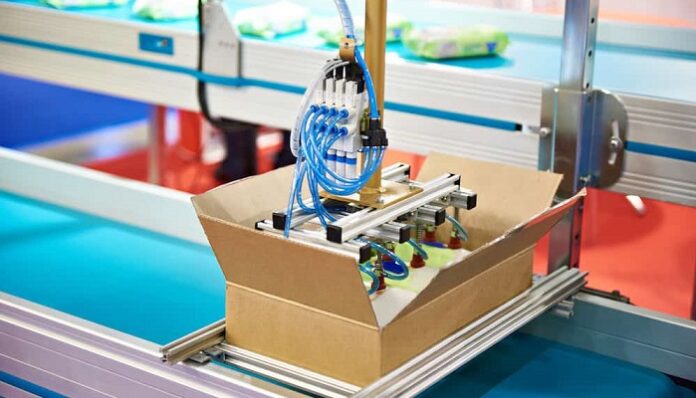

It is a well-known fact that the packaging industry is one of the many that has been witness to incredible, transformative digitization as well as automation in recent years.

Manufacturers as well as producers across the world have gone on to become increasingly dependent on sophisticated, innovative automated technology in order to inspire new product development efficiency improvements and ideas, while at the same time reaping the benefits when it comes to cost savings due to less manual intervention.

But the impact of such widespread advancements is not exclusively limited to the packaging producers, or, say, the manufacturers. Automation also happens to be reshaping the role of wholesale distributors, which is yet another crucial component of global supply chains.

Wholesale Packaging Spaces That Are Evolving

Wholesale product distributors happen to play a vital role in connecting suppliers with buyers, whether in terms of acting as an intermediary or proverbial middle person, managing inventory, aggregating orders, or even offering logistics services.

They happen to have a broad range of businesses that are based on their distribution network, locale, kind of product, and also relationship to their buyers as well as suppliers, if in case they have any. Tens of thousands of wholesale businesses go on to sit in supply chains worldwide, having such businesses that happen to range broadly from artisan bread roll suppliers based out of the UK to luxury textile distributors located in South America.

The salient trait is that wholesalers’ involvement makes sure of a more seamless transition from manufacturers packaging products as well as materials to delivering them to end users.

However, as consumer expectations have gone on to change rapidly post-COVID and as market dynamics have gone on to evolve, wholesale distributors must go on to embrace automation in order to avoid falling behind. They happen to be under increased pressure to embrace as well as refine their strategies so as to keep supply and demand at certain equitable and manageable levels, which happens to be easier said than done.

The surge when it comes to e-commerce, especially, has indeed been a major disruptive force when it comes to wholesalers, but it has also gone on to present various opportunities for wholesalers to go ahead and adapt to new markets along with consumer demands more strategically.

Retailers, especially in the packaging as well as logistics sectors, now go on to anticipate much faster response times, flexible order convergence, and much greater transparency into stock levels. Meeting such kind of demands can be quite challenging for wholesalers, which happen to rely on tried-and-tested manual processes as well as legacy systems, however, it is automation can be the answer to unlocking and taking advantage of such new opportunities.

Which Wholesalers Can Get Benefited From Automation?

While classifications may go on to vary, wholesalers typically happen to sit in a loosely defined category when it comes to suppliers. Wholesalers may as well purchase goods in bulk and often go on to import products for resale, and they can also be classified by factors like location, distribution network, or even the types of goods they offer.

Classifying the types of wholesalers that can benefit from automation requires a thorough look at their present short- and long-term issues.

For Example:

– Local or even regional wholesalers happen to be usually based in the same region as their buyers and suppliers if they make use of them, which means that they do need to automate processes so as to upscale and grow.

– Meanwhile, national as well as international wholesalers export products across the globe, but they may have identified some fresh buyer markets to target, which is made quite easier due to automation.

– Numerous wholesalers can go ahead and automate the supply and distribution of non-critical or even routine goods.

– Wholesalers can make use of tech to go ahead and revamp as well as improve regularity as well as the schedule of services, which means that they can fulfill more orders.

– Remote wholesalers can go on to leverage digitization as well as technology in order to work and distribute products with no physical presence required. They may need to automate routine as well as manual processes in order to maximize resources.

Whether they happen to be local or remote suppliers offering non-critical, routine, or perishable goods, or they are national or international and go ahead and supply strategic commodities, any wholesaler can go on to benefit from automation.

What Happen To Be The Benefits of Wholesale Automation?

Integrating automation, along with emerging artificial intelligence- AI solutions, into their operations can enable wholesalers to unlock a range of business-transforming advantages.

1. Rising efficiency as well as productivity

Automation can go on to help wholesalers witness a dramatic rise in productivity and efficiency. By way of automating repetitive as well as time-intensive tasks like inventory management, invoicing, and order processing, wholesalers can mitigate the risk of human error and also free their teams to go ahead and focus on more high-value activities.

For instance, robotic process automation- RPA can be a kind of a tremendous time- and resource-saving solution in the case of order fulfillment and verification, while at the same time reducing order-to-delivery time and also keeping precision high.

2. Cost savings as well as improved profitability

Automation happens to be often correlated with short- and long-term cost savings when it comes to wholesale packaging distributors within the retail space. Automating labor-intensive tasks can go on to reduce wholesalers’ reliance, especially on manual labor, and, hence, lower overhead expenses. Automating the balancing of accounts payable and receivable also means that the risk of financial inaccuracies when it comes to invoicing is decreased.

Making utmost use of automated predictive analytics can go on to help wholesale distributors make informed pricing decisions, altering rates based on market conditions and customer demand. Automatic order management also helps in faster and more dependable order fulfillment, thereby directly enhancing the customer experience.

3. Greater visibility of the stock

Wholesale distributors can go on to leverage automation in order to enhance inventory management. With the aid of real-time asset management solutions as well as enterprise-grade tracking technologies, facility managers can go on to gain greater control and visibility when it comes to their asset locations, history, and movements.

With this elevated oversight, wholesalers can go on to reduce the risk of overstocking or even understocking the assets by way of using real-time data in order to optimize their storage as well as transport processes, while at the same time managing costs.

4. Sustainability

Making supply chains much more transparent and sustainable is yet another top priority for retail buyers as well as suppliers, and wholesalers can go on to leverage environmentally-friendly packaging as well as fulfillment processes due to automation. In turn, this is going to help them gain a kind of unique competitive advantage.

Integrating Internet of Things- IoT technologies with wholesalers’ procurement and logistics workflows can help them to the utmost use of transport routes so as to minimize emissions and, at the same time, ensure compliance with sustainability standards.

Overcoming Obstacles To Wholesale Automation

In spite of the clear benefits of automation, many wholesale packaging distributors may still need to be more open when it comes to embracing these transformative technologies.

Wholesale facility employees may indeed be hesitant so as to adopt new automated systems with a bent toward manual processes, fearing loss of control as well as long-term job displacement. Blending automation solutions with the incumbent IT systems as well as resources can indeed be intricate and time-consuming, often requiring careful resource planning ahead of time.

Not just this, but upfront costs that are associated with upending infrastructure as well as operations can be high, needing a substantial investment right from the start. Many wholesalers may also not have the in-house technical expertise so as to roll out and test automated systems sans the external assistance.

In order to overcome these obstacles so as to unlock the power of automation, wholesale distributors must take a strategic, phased approach that involves:

• Conducting a stringent evaluation of their existing processes

• Identifying the most promising opportunities when it comes to automation

• Opting for flexible, scalable automation platforms that go on to suit their requirements the best

• Testing solutions in order to ensure they can be seamlessly integrated with their existing systems

• Investing in a comprehensive employee training scenario and change management initiatives so as to make sure of a smooth transition

Through addressing such kind of implementation challenges proactively, wholesale packaging distributors can go ahead and unlock the overall potential of automation and make their position in global supply chains more robust.

Moreover, they can also position themselves in terms of long-term success in a market poised for consistent turbulence in weeks and months to come, while at the same time also driving enhancements in distribution as well as packaging efficiency, customer experience, sustainability, cost savings, and inventory control.