The requirement when it comes to caring for pharma’s in transit has never before been so high. With instability within the political spectrum reigning high and also affecting global trade routes as well as fragile economics, thereby causing the pharmaceutical industry to be more cautious than usual, the risk of vaccines along with other temperature-sensitive medications getting spoiled during transit is completely unacceptable.

For this reason, there are many throughout the industry who happen to be embracing a range of cold chain technology so as to improve resilience when it comes to challenging operating conditions, in order to increase efficiency as well as comply with strict regulatory standards.

The major cold chain technologies that are in use are:

1. Internet of Things- IoT

IoT-led cold chain devices help users monitor the temperature of their respective consignments and the environmental conditions in which they happen to be exposed, and that too in real-time throughout the part of transit and storage phases. IoT technology happens to be incorporated into cold chain packaging as well as storage units so as to enable pharmaceutical companies to go ahead and continually track and evaluate the generated data, thereby making sure of quality control and helping with the swift corrective action that needs to be taken in the event of any deviations.

2. Blockchain technology

Blockchain technology is indeed all set to revolutionize the way in which pharma is monitored across the cold chain, thereby elevating the level of transparency and trust among stakeholders. The ledger, which happens to be built by this unique cold chain technology, happens to be unalterable and safe, thereby helping all the stakeholders involved to access the same data and information at any point in time, hence making sure of regulatory compliance as well as decreasing the risk when it comes to tampering.

3. Automation

Numerous kinds of temperature alterations take place across the manual loading as well as unloading process, and this process happens to be regarded as high risk for packaging to be dropped or knocked, thereby disrupting contents and at the same time potentially causing contamination issues. Automated loading as well as unloading systems eradicate this risk, speed up and streamline the process, and at the same time, improve reporting.

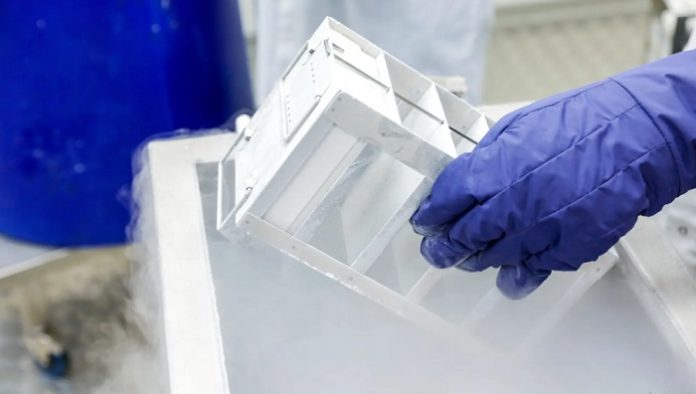

4. Cold chain packaging

A critical cold chain tech that has been taken into account by many pharmaceutical companies is the use of passive cold chain containers along with integrated data loggers. Supplied by companies like Tower Cold Chain, such innovative, hygienic, as well as reusable packaging solutions decrease the environmental effect of shipping pharmaceuticals across the world, help financial forecasting, and decrease the risk to pharma companies of their products spoiling during transit.

The exact cold chain packaging happens to be essential so as to ensure regulatory compliance as well as patient safety; hence, investing in top-of-the-range packaging goes on to offer an essential safeguard to the prominent medications as well as vaccines dispatched every day by pharmaceutical companies across the world.

Summary

Cold chain tech when it comes to the pharmaceutical sector, happens to be evolving quite rapidly and goes on to offer numerous advantages to manufacturers as well as suppliers of temperature-sensitive medications. By way of integrating state-of-the-art passive packaging, IoT, along with blockchain technology, as well as automating the riskiest processes, pharma companies can see a future in which money does not get wasted on unsuccessful deliveries, patient outcomes get enhanced, and the supply chain gets much more efficient.