Petroleum-derived plastics, which happen to be one of the most frequent synthetic materials, go on to exhibit a variety of advantageous traits, which include excellent waterproof capabilities, cost-effectiveness, efficient barrier properties, high mechanical robustness, and also the ease of processing. In the recent decades that have gone by, synthetic plastics have been utilized in an extensive way as packaging materials all across various industrial applications and also in daily life, such as food preservation, care products, electronics, and even apparel. However, the dependence on non-renewable plastics goes on to raise prominent concerns with regard to the depletion of limited petroleum resources as well as greenhouse gas emissions during their disposal as well as production. The statistics go on to indicate that almost half of the global production when it comes to solid plastics happens to get discarded across the world every year. Besides this, the conventional plastics may also accumulate within the soil or even enter the ocean because of their non-reputable as well as inadequate disposable methodology, which results in detrimental effects on the ecosystem of the planet.

At present, the primary strategies when it comes to managing plastic waste go on to involve landfilling as well as incineration, which can go ahead and generate substantial GHG emissions and also occupy land resources. In spite of the fact that recycling happens to be considered as a potential strategy in order to decrease plastic accumulation, only less than 9% of the global plastics get recycled because of the high costs as well as time consumption that are associated with recycling processes and the diminished quality along with properties in terms of recycled polymeric materials. Given the rising environmental awareness as well as stringent regulations, the adoption of biodegradable alternatives happens to represent a feasible strategy in terms of addressing the strict barriers that are associated with plastic waste.

At present, the plastics can be categorized as per their source and biodegradability. For instance, bio-based polyethylene terephthalate happens to be derived from renewable sources, but it is not biodegradable. Polycaprolactone as well as polybutylene succinate (PBS) are biodegradable, but they are still synthesized by way of using petroleum sources. As society shifts away from fossil sources, bioplastics, which go on to cover bio-based as well as biodegradable materials, have gained a lot of traction and attention across the world since more sustainable choices to conventional petrochemical-derived plastics, which can reduce the fast plastic chemical accumulation and also decrease the GHG emissions that are associated with conventional plastic production, have come into the picture.

However, the recent research has gone on to indicate that some bioplastics, like polylactic acid, polyhydroxyalkanoates, and polyhydroxybutyrate, happen to be nondegradable under the aegis of soil or marine environments, thereby leading to the formation of microplastics, which happen to pose a very serious barrier to the environment as well as human health.

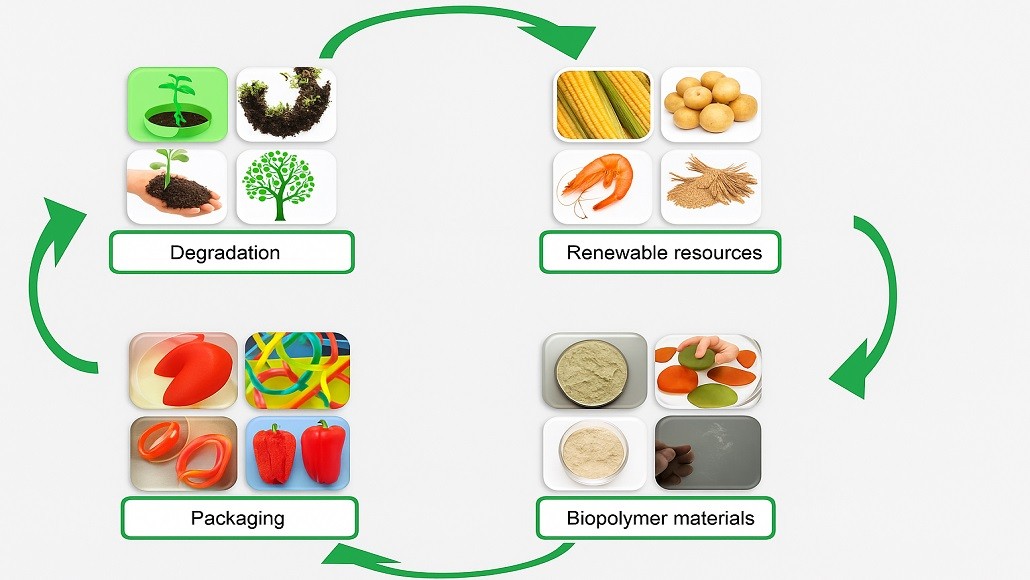

Taking into account the above-stated barriers, there is indeed a very immediate need to utilize renewable biomass sources as well as national biopolymers as alternative sources when it comes to the development of bioplastic materials. Their biodegradable nature, non-toxicity, and environmental friendliness go on to endow biopolymers ideal for processing within advanced bioplastic materials, which are applicable in the fields of textiles, food packaging, electronics, construction, and biomedicine.

It is well to be noted that packaging films have gone on to garner prominent interest within food storage as well as preservation. There are recent advancements in biodegradable active packaging technology that have led to the emergence as well as innovation of food packaging solutions that are based on proteins.

Because of their renewable, abundant, and biodegradable characteristics, proteins, when it comes to both plant and animal origins, have gone on to be considered very promising components when it comes to the development of bioplastic materials. Besides this, protein-based packaging films are also gaining a lot of popularity because of their versatility, accessibility, and edible nature in certain instances.

In recent years, which have gone by, there has been a rising focus when it comes to incorporating plant-based protein within the formulation of protein-based bioplastic films because of their lower environmental effect, higher production yield, less carbon footprint, and also high sustainability footprint vis-à-vis the animal protein.

Zein Protein, the primary alcohol-soluble prolamine originating from the corn, happens to constitute a prominent protein component within its products that are generated by way of milling processes of maize starch as well as oil production. Traditionally regarded as protein waste, zein has been predominantly rolled out in animal field applications. There are recent innovative applications that have gone on to take advantage of the hydrophobicity, biocompatibility, eco-friendliness, and cost-effectiveness of zein protein, thereby having its application within the development of coatings, adhesives, textiles, fibers, films, and plastics.

The primary limitation when it comes to protein-based bioplastics comes from the inherent properties of native protein monomers, which go on to pose challenges within film processing and also result in bioplastics having inferior barrier properties, chemical stability, low mechanical robustness, and high oxygen permeability, as well as sensitivity when it comes to water and humidity.

It is well to be noted that protein-based bioplastic films often fail to meet the required criteria in terms of food preservation, especially with regard to mechanical properties as well as wet stability. In order to address these barriers, self-assembly in terms of protein monomers within amyloid fibrillation aggregates has gone on to emerge as a very promising approach in order to elevate the performance as far as protein-based materials are concerned.

Amyloid fibrils—AFs, which are distinguished because of their characteristic cross-β structures, can be derived from a diverse range of proteins, which include the abundantly available industrial byproducts.

The functional properties when it comes to AFs go on to outperform the native protein monomers, which has gone on to make them get utilized within the development of sustainable as well as renewable biotic films.

Examples when it comes to AF-based bioplastic films go on to include whey protein AF-based bioplastic film, hen lysozyme AF-based bioplastic film, rapeseed protein AF-based bioplastic film, and soy protein AF-based bioplastic film. But there are only limited studies that have gone on to report the development of bioplastic films that use food protein, amyloid fibrils, which goes on to warrant more investigation of certain other protein systems as well as the performance of amyloid-based bioplastic in terms of .

The study focused on developing a sustainable bioplastic film, which is composed of zein protein, amyloid fibrils, and methyl cellulose when it comes to food packaging materials. To go ahead, we induced the amyloid fibrillogenesis of ZP and then went on to characterize the properties of ZPAF by way of using spectroscopic as well as microscopic tools. ZPAF-based bioplastic films that have varied ZPAF content were prepared by way of chemical crosslinking teamed with the addition of plasticizer. The chemical crosslinking between the MC as well as ZPAF went over to get verified by way of using Fourier-transform infrared spectroscopy.

The influences when it comes to bioplastic composition on the film thickness, mechanical properties, surface microstructures, and thermal balance of ZPAF-based films were examined by way of using a range of analytical instruments. Given that the water vapor barrier along with antioxidant activities as well as UV shielding performance of bioplastic films can go ahead and contribute to extending the shelf life of food products, there was an evaluation done of these properties of MC bioplastic films as well as ZPF-based bioplastic films.

The effect when it comes to ZPAF content within the water vapor barrier, UV-shielding performance, and also antioxidant activity of the bioplastic film was investigated. And finally, the properties of ZPAF-based bioplastic films were characterized in terms of total food migration, biodegradability, and regeneration, and these properties were then compared to those of MC bioplastic films. This research also showcases an incredible example of making use of plant protein-based amyloid fibrils as building blocks within the production of environmentally friendly, renewable bioplastic materials when it comes to food packaging and preservation.