TOPPAN Holdings from Tokyo has gone on to acquire patented technology from Asahi Kasei Corporation, which is related to brittle lidding materials for push-through blister packs. The said move highlights the ambitions of the group when it comes to sustainable pharmaceutical packaging. Notably, transfer of the technology was accomplished on November 28, 2025, confirmed TOPPAN on December 12.

The transaction goes on to give TOPPAN the ownership portfolio of 12 patents, which includes a core patent that covers brittle film materials that are designed to roll out dependable push-through performance. Through integrating the acquired technology with its present barrier film, packaging, and printing capabilities, TOPPAN is indeed positioning itself in terms of a full-scale entry into the global push-through blister pack market.

The move is due to the fact that the pharmaceutical packaging gamut faces rising pressure so as to decrease the environmental effect, especially in Europe, where the regulatory frameworks and also the corporate sustainability commitments are speeding up the shift away from the aluminum-intensive as well as multi-material formats. Blister packs, apparently, still remain one of the most broadly used pharmaceutical packaging formats across the world; however, their traditional construction, which typically combines aluminum foil lidding along with PVC or polypropylene bases, goes on to pose quite a prominent challenge in terms of recycling along with circularity.

TOPPAN confirmed that the newly acquired brittle lidding tech directly goes on to address this issue between sustainability and performance. When we talk of pharmaceutical packaging, aluminum foil has long been depended upon so as to attain the high barrier traits that are needed to safeguard the sensitive drug products. But it also goes ahead and represents a prominent obstacle to material simplification as well as recycling.

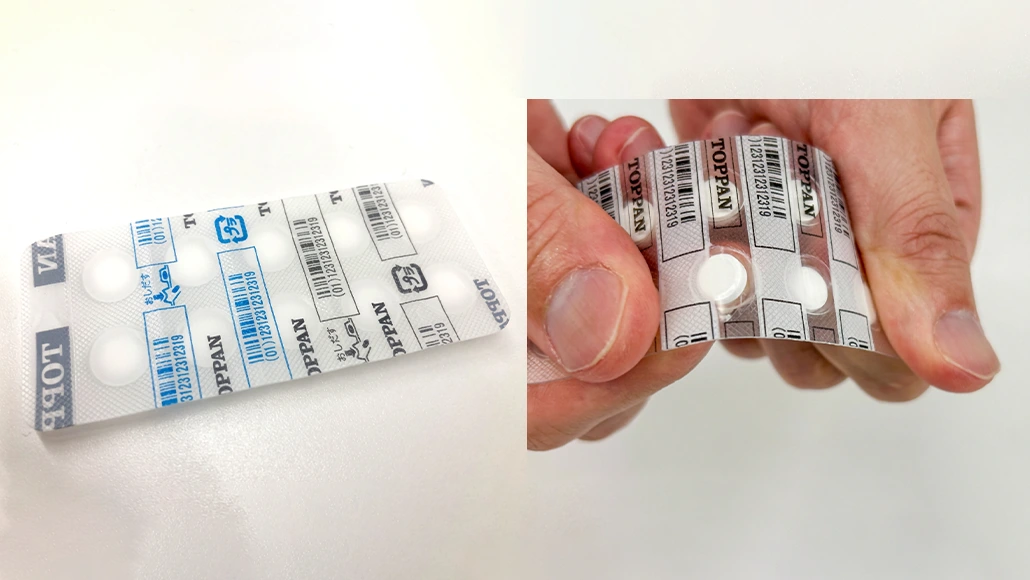

Through combining brittle film technology along with its proprietary GL BARRIER transparent barrier films, TOPPAN looks forward to developing aluminum-free blister pack designs that maintain push-through functionality along with barrier performance. The company opined that this approach opens the door to push-through blister packs, which are based on polyolefin materials like polypropylene, helping with both aluminum-free as well as mono-material configurations.

It is well to be noted that mono-material blister packs are growingly being viewed as a crucial step towards elevating the recyclability element. Conventional push-through blisters make use of varied materials for the base as well as lidding, thereby complicating waste separation along with processing. TOPPAN said that the use of polypropylene for both the blister base as well as the brittle lidding layer could help the mono-material designs, which better align with the emerging recycling systems as well as regulatory anticipations.

The company also went on to underline the role of its printing technologies when it comes to supporting sustainability objectives. TOPPAN said that its portfolio goes on to include eco-friendly printing processes like water-based flexographic printing, which helps in minimizing the solvent usage while at the same time enhancing the print quality. Applied to blister packaging, these technologies could very well go on to improve consumer-facing visibility along with traceability while at the same time further decreasing the environmental effect.

Apparently, this acquisition fits into the broader strategy by TOPPAN Holdings of combining the digital transformation along with the sustainability transformation in order to address what it goes on to describe as priority social challenges. In its packaging business, the group has been expanding the development as well as the supply of environmentally conscious packaging solutions, with a special focus on contributing toward a circular economy.

Pharmaceutical packaging has notably emerged as a major focus area within this strategy. While the demand when it comes to more sustainable solutions is indeed growing by the day, the strict quality and safety as well as stability requirements of the sector have limited the speed of material change. TOPPAN remarked that the acquired technology makes its ability to meet these needs more robust while at the same time decreasing dependence on aluminum as well as multi-material structures.

Going forward, TOPPAN said that it does plan to complete the development of functional as well as eco-friendly push-through blister packs by way of using the acquired technology by the 2025 fiscal year-end. Samples are anticipated to be made available as part of this development phase, since the company prepares for the commercial expansion when it comes to next-gen blister packaging.

Interestingly, the initiative is going to be positioned under the SMARTS™ sustainable brand of TOPPAN Group, which brings together packaging technologies with digital marketing as well as business process capabilities. By way of SMARTS™, TOPPAN said it looks forward to offering sustainability-focused solutions throughout the value chain, working with stakeholders in order to support the shift to more environmentally responsible packaging systems.

As the regulatory scrutiny intensifies and pharmaceutical companies re-evaluate the packaging footprints, the acquisition by TOPPAN goes on to signal a rising convergence between advanced materials science and sustainability-driven design when it comes to one of the most demanding segments within the packaging sector.