Is real-time tracking the new normal for AI and IoT in logistics?

AI and IoT are having a huge impact on logistics, transforming the way goods move across the world. These technologies are making real-time monitoring more and more common. This implies that firms may always know where their goods are, whether they are crossing the ocean or merely leaving the warehouse.

People used to have to depend on updates that were hours or even days old. Now, thanks to sensors and sophisticated software, updates arrive right away. This feature helps companies prevent delays, solve issues more quickly, and make customers happier since everyone knows what’s going on with their shipments.

It seems like real-time tracking will soon be a must-have in the logistics field. It saves time and money and helps you create trust with your customers. Real-time monitoring is no longer simply a passing fad; it’s now a key aspect of logistics as more firms start to use AI and the Internet of Things.

The New Look of Logistics: Using AI and IoT

Logistics operations depended a lot on manual work, updates that weren’t always on time, and prompt answers from management for many years. But AI and the Internet of Things (IoT) have changed the logistics sector forever. Smart sensors are now built into fleets, containers, shipments, and even single things. These sensors send data across large networks all the time. When AI-powered systems use these data streams, they can make predictions, find the best pathways, and take action before problems become worse.

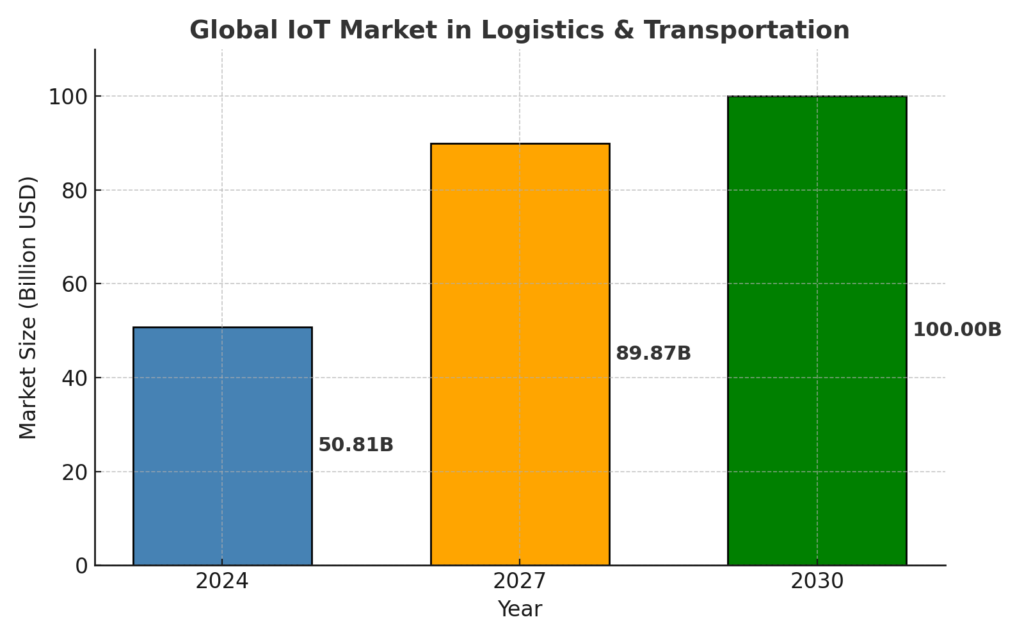

A new estimate says that by 2030, the worldwide IoT industry for logistics and transportation will be worth more than $100 billion, up from $50.8 billion in 2024. This fast increase isn’t simply a trend; it’s a big change in the industry towards using real-time analytics. AI and IoT in logistics are no longer simply concepts for the future; they are fast becoming important parts of the profession.

The Rise of a New Standard in Real-Time Tracking

Real-time tracking is at the centre of this change. This is a game-changing feature that is achievable because AI and IoT work together so well. Older monitoring technologies typically provide us updates that are incomplete or late. Real-time tracking, on the other hand, gives us a full perspective of the whole supply chain. Everyone who is involved can get live information on the status, location, temperature, and more of a cargo from the time it leaves the warehouse until it gets to its ultimate destination.

So, what makes real-time tracking the new standard? The answer is in the many things it can do for you. People don’t simply want their packages to arrive on time anymore; they also want to know what’s going on and trust that it will happen. Deloitte’s 2022 study of logistics experts revealed that 70% of them said end-to-end visibility is the major reason they use digital solutions. Logistics companies may match these expectations by using real-time tracking, which reduces uncertainty and builds confidence throughout the value chain.

Deloitte’s research from May 2024 shows that logistics still places a high value on end-to-end visibility and supply chain resilience. The “Trade in Transition 2024” initiative found that 97% of the firms who answered the poll by the end of 2023 were actively changing their supply chains. This is up from 92% in 2022. This suggests that people are more and more committed to making the supply chain more open and flexible.

How AI and IoT Work Together to Make Real-Time Tracking Possible

IoT devices and AI algorithms work together in a stunning way to make real-time tracking possible. IoT sensors are attached to almost any asset you can think of, such vehicles, shipping containers, and pallets. They are always collecting information on where they are, what the weather is like, and even how healthy the assets are. After that, this information is delivered to central platforms by cellular, satellite, or mesh networks.

AI is quite important in this arrangement since it sorts through all the incoming data. Machine learning models are made to find problems, guess when deliveries will arrive, and offer ways to avoid delays or losses. AI may, for instance, change the route of shipments on the fly depending on traffic, bad weather, or political problems. This helps cut down on downtime and expenses.

A McKinsey & Company research from 2024 revealed that businesses who used AI and IoT in their logistics witnessed a 20–30% increase in operational efficiency and a 40% decrease in shipments that were lost or delayed. These numbers show that AI and IoT in logistics make real-time tracking work better, not only in terms of visibility but also in terms of overall performance.

Real-Time Tracking in Action: Use Cases in Business

You can find real-world examples of how AI and IoT may be used for real-time tracking in logistics all over the place. For example, in cold chain logistics, it’s very important to maintain temperature-sensitive commodities like vaccinations or fresh fruit inside precise temperature restrictions. IoT sensors check the temperature every minute, and AI algorithms instantly spot any changes and take steps to stop rotting.

Port operations are another fantastic example. Big shipping corporations like Maersk and DP World are now employing IoT-enabled asset monitoring and AI-driven analytics to speed up the transportation of containers and cut down on turnaround times. This has led to faster customs clearance, less delays, and better service dependability.

E-commerce sites are also getting in on the fun by using real-time monitoring to meet the increased need for delivery on the same day or the following day. These organisations may use AI and IoT in logistics to provide clients real-time order monitoring, precise estimated time of arrival (ETA) forecasts, and timely alerts if there are any delays.

Getting beyond problems like data security, scalability, and integration

The benefits of AI and IoT in logistics are clear, but there are also problems that need to be solved in order to make real-time monitoring the standard. Data security and privacy are very important, particularly when shipping and customer information is so sensitive. It’s important to follow rules like GDPR and have effective cybersecurity safeguards in place.

Another problem is scalability. Logistics organisations need to buy cloud solutions and sophisticated analytics that can grow with their needs since millions of linked devices are sending petabytes of data. Also, adding AI and IoT to existing business systems and older technology requires careful planning and good change management.

That being said, these problems are becoming easier to deal with as technology becomes better and prices go down. Leaders in the industry are already setting the pace, and others are keen to stay up in this fast-paced world.

The Road Ahead: From Differentiator to Must-Have

As AI and IoT become better in the logistics field, real-time tracking is going from being a nice-to-have to a must-have. The advantages, such as a better customer experience, less risk, and more efficiency, are just too significant to ignore. Experts say that by 2027, more than 80% of logistics organisations across the world will be using some kind of AI- and IoT-powered real-time tracking.

Also, regulatory bodies and industry organisations want logistics to be more open and traceable, which is making real-time monitoring the new standard in the field.

Conclusion: Setting the Course for the Future of Logistics

The question “AI and IoT in Logistics: Is Real-Time Tracking the New Standard?” isn’t simply a casual one; it shows how important and urgent the sector is right now. There is no doubt that AI and IoT in logistics are changing the future, and real-time tracking is a big part of it.

Logistics companies, shippers, and consumers all need to accept this new norm. People that invest in real-time monitoring enabled by AI and IoT will be at the forefront of an industry that values resilience, agility, and trust. Real-time tracking will go from being a nice-to-have to a must-have as logistics becomes digital faster.