SEALPAC will return to Seafood Expo 2026 in Barcelona, citing the continued rise in global seafood consumption and the growing need for smarter, more sustainable packaging solutions. As consumers increasingly prioritise healthy and sustainable diets, demand for fish and seafood products remains strong, intensifying pressure on manufacturers to maintain freshness, ensure safety and reduce environmental impact.

At stand 3LL200, the Germany-based packaging specialist will present its latest technologies for the global seafood industry. Among the highlights is the renowned and proven FlatSkin® concept, demonstrated on a SEALPAC M-Flex traysealer. The company will also stage its Supermarket of Innovations, showcasing numerous innovative seafood packaging concepts from international markets, all produced on SEALPAC equipment. The display is intended to provide seafood companies with practical inspiration to further develop their packaging concepts and respond to changing market requirements.

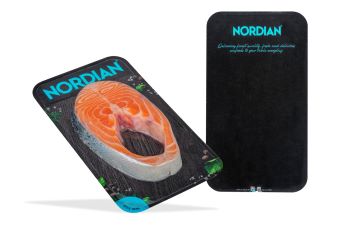

Several years ago, SEALPAC introduced the FlatSkin® packaging system in response to increasing demand for environmentally responsible packaging. The concept combines prolonged shelf life with attractive product presentation and sustainable material usage. Designed for a wide range of seafood products, FlatSkin® enables vertical presentation at retail. Fresh salmon, for example, is sealed under deep vacuum directly onto a flat cardboard carrier featuring an ultra-thin plastic liner. A highly transparent skin film fixates the product to the cardboard base. After product removal, the thin plastic liner can be easily separated to allow for individual disposal. The cardboard base supports double-sided printing, creating additional branding opportunities. Overall, the system delivers a reduction in plastic usage of up to 75% compared to traditional vacuum skin packaging.

Several years ago, SEALPAC introduced the FlatSkin® packaging system in response to increasing demand for environmentally responsible packaging. The concept combines prolonged shelf life with attractive product presentation and sustainable material usage. Designed for a wide range of seafood products, FlatSkin® enables vertical presentation at retail. Fresh salmon, for example, is sealed under deep vacuum directly onto a flat cardboard carrier featuring an ultra-thin plastic liner. A highly transparent skin film fixates the product to the cardboard base. After product removal, the thin plastic liner can be easily separated to allow for individual disposal. The cardboard base supports double-sided printing, creating additional branding opportunities. Overall, the system delivers a reduction in plastic usage of up to 75% compared to traditional vacuum skin packaging.

For manufacturers requiring high outputs and maximum efficiency, SEALPAC’s Amax-series traysealers are designed for continuous, high-speed packaging. The machines process various tray formats, tray materials and packaging concepts, including resource-saving solutions such as ultra-light, hybrid or mono-material trays. Equipped with the fastest tool changeovers on the market, they are suited to frequent product changes. Reliable processes and low costs per package are aimed at enabling a swift return on investment.

Smaller-scale operations are addressed with the semi-automatic M-Flex traysealer. Developed for artisanal fish processors, start-ups, catering providers and delicatessen stores, the compact system delivers professional-grade packaging within a limited footprint. Despite being semi-automatic, it supports the full range of SEALPAC’s packaging concepts, including FlatSkin®, Modified Atmosphere Packaging (MAP) and sealing-only applications. Its servo-driven film transport ensures precise control, even when handling complex packaging concepts. The M-Flex traysealer will be demonstrated live at Seafood Expo 2026.

SEALPAC will also present its high-performance F-series thermoformer range, developed with availability as a central design priority. Features such as automatic film alignment, automatic chain tension correction and continuous process monitoring are intended to reduce manual intervention and minimise unplanned downtime. The hygiene-focused design, easy-to-clean construction and simplified maintenance contribute to operational efficiency. Film reels as well as forming or sealing tools can be exchanged with minimal effort through dedicated quick exchange systems, accelerating changeovers and enhancing operator safety. Optimised energy and air consumption reduce ongoing operating costs. The combination of high process reliability, maintenance-friendly design and reproducible output supports rapid payback, particularly at high production volumes of seafood products.

As seafood consumption continues its upward trajectory, manufacturers and retailers face the dual challenge of preserving product freshness and meeting sustainability expectations. Through its FlatSkin® concept and its portfolio of Amax-series traysealers, M-Flex traysealer and F-series thermoformers, SEALPAC aims to address these demands across a broad spectrum of production scales at Seafood Expo 2026 in Barcelona.

As seafood consumption continues its upward trajectory, manufacturers and retailers face the dual challenge of preserving product freshness and meeting sustainability expectations. Through its FlatSkin® concept and its portfolio of Amax-series traysealers, M-Flex traysealer and F-series thermoformers, SEALPAC aims to address these demands across a broad spectrum of production scales at Seafood Expo 2026 in Barcelona.