In recent years, augmented reality-enhanced personalised packaging has presented itself as a useful weapon for businesses seeking to add greater value at the product level. Formerly perceived mostly as a retail strategy, augmented reality (AR) is now assisting enterprises in simplifying communication, enhancing transparency, and facilitating everything from training to traceability.

In industries such as pharmaceuticals, food and beverage, and industrial manufacturing, where precision, regulation, and process clarity are paramount, packaging is increasingly serving as a digital touchpoint. With the swipe of a code, what was previously only a box or label is now an avenue for focused information, role-specific news, or product training. This transformation is redefining how companies approach packaging—not as a destination, but as the beginning of an intelligent experience.

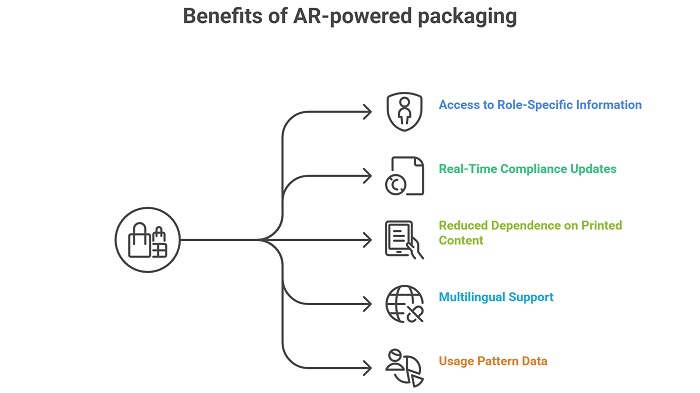

Why Businesses Are Embracing AR-enabled Packaging

With increasingly sophisticated supply chains, businesses are looking to AR to get more out of packaging.

- Access to role-specific information: from safety procedures to storage guidelines

- Real-time updates for compliance: links to the most current certificates or data sheets

- Less dependence on printed content: instructions and guides digitally accessible

- Multilingual support and localization: content relevant to user location or settings

- Usage pattern data: what information buyers are consuming and how they are consuming it

All of these features are not only enhancing the end-user experience but are also enabling brands to remain closer to buyers, distributors, and partners across the lifecycle of the product.

AR Transforms Packaging into a Communication Vehicle

The actual benefit of AR-enabled packaging is its flexibility. Content is not static; it can be updated or modified in real time without having to reprint anything. This is more convenient for businesses to remain up-to-date, even when specifications, certifications, or messaging must be changed.

For procurement teams, it means immediate access to prices or sustainability data. For operations, it can provide training videos or live inventory information. And for marketers, it provides a direct channel of communication at the point of use—one that doesn’t necessitate email campaigns or websites.

The packaging essentially becomes part of the service. It streamlines onboarding, enables compliance, and confirms accurate handling without causing friction or paperwork. That matters particularly in industries where products cross borders, through multiple stakeholders, and into regulated surroundings.

Enabled by Public Standards, Not Locked Systems

One of the principal reasons AR-enabled packaging is a viable prospect for businesses today is the emergence of open standards. The European Union’s Digital Product Passport program, under the umbrella of its Circular Economy Action Plan, is intended to provide an environmentally conscious and traceable digital identity to products. This enables both buyers and suppliers to gain access to environmental and compliance information in a standardised format.

The GS1 Digital Link standard is yet another open framework in broad use. Applied across industries such as logistics, healthcare, and food, it makes possible one QR code to grant access to a defined set of product information—ingredients, specs, certifications, and more. These open systems make AR-enabled packaging usable at scale, regionally, and without reliance on closed platforms.

For packaging and procurement professionals, the change translates into AR capability being integrated without technical complexity or risking vendor lock-in. It also translates into content being centrally maintained and consistently delivered, including across multi-country supply chains.

Real Examples from Around the Value Chain

In the drug industry, AR-enabled packaging is already assisting hospitals and pharmacies by providing spot video instructions on correct storage and dosage, just by scanning a pack.

Cosmetics manufacturers are employing AR packaging to display ingredient sourcing information or usage tutorials—beneficial for distributors and retail buyers who desire more than just a printed label.

In manufacturing industries, equipment and parts tend to be shipped with AR overlays that guide the technicians through steps of installation or safety protocols. This eliminates the use of printed guides and can avoid mistakes in the field.

Food and drink brands are beginning to employ AR to convey certifications (such as organic or fair trade), display environmental data, or even connect packaging to live event promotions, all for shoppers interested in a richer knowledge about the product they are buying.

What’s Still Developing

While adoption increases, some of the practicalities remain in development. Web-based AR (WebAR) is addressing one challenge: accessibility. Users can access AR content from their browser without needing to download an app. This makes a difference where convenience and speed are essential.

Content maintenance is another area to watch. As AR content can be changed, firms have to have a plan in place for ensuring it remains up-to-date and accurate. Luckily, cloud platforms are simplifying the ability to manage what is seen when one scans a pack with minimal IT support required.

More significantly, the mindset for packaging is changing. Rather than asking, “How much does the pack cost?” procurement teams are now beginning to ask, “What does the packaging do?” And when it can facilitate onboarding, compliance, communication, and tracking—it does a lot.

The New Value Layer in Packaging

In an industry defined by speed, regulation, and ecological concerns, augmented reality-enabled personalised packaging offers a clear advantage. It transforms packaging from more than just a cost—it transforms it into a channel.

For marketers, it’s a point of interaction. For logistics, it’s a means to streamline information. For compliance teams, it minimises paperwork and error. And for buyers, it ensures products arrive with clarity, transparency, and value built-in.

AR-enabled packaging is a pragmatic, scalable innovation of what packaging can do in the business environment. With public standards behind it and technology being easier to implement, it’s no longer a question of adding AR—it’s a question of adding intelligence, flexibility, and functionality to every product that is shipped.