Packaging, which was once simply about product protection and branding, has now become a strategic priority for companies as the world of consumption is evolving. Further, resource constraints, waste management, and carbon emission regulations have made strategic decision-making in packaging more important than ever. As consumer awareness grows, the demand for sustainable packaging, especially in FMCG (fast-moving consumer goods) packaging, has risen. One of the most effective strategies the packaging industry is adopting to address this is the use of lightweight materials that can reduce the impact on the environment and also improve transportation, logistics, and consumer convenience.

FMCG products are quickly sold and hence have the potential to generate significant volumes of packaging waste worldwide. Thus, by using lightweight materials for packaging, the packaging weight can be reduced, which in turn reduces the amount of waste generated. It also means lower transportation costs and a smaller environmental footprint. Apart from this, today, brands are increasingly judged on their commitment to sustainability. This makes innovative packaging not just a regulatory necessity but a commercial opportunity.

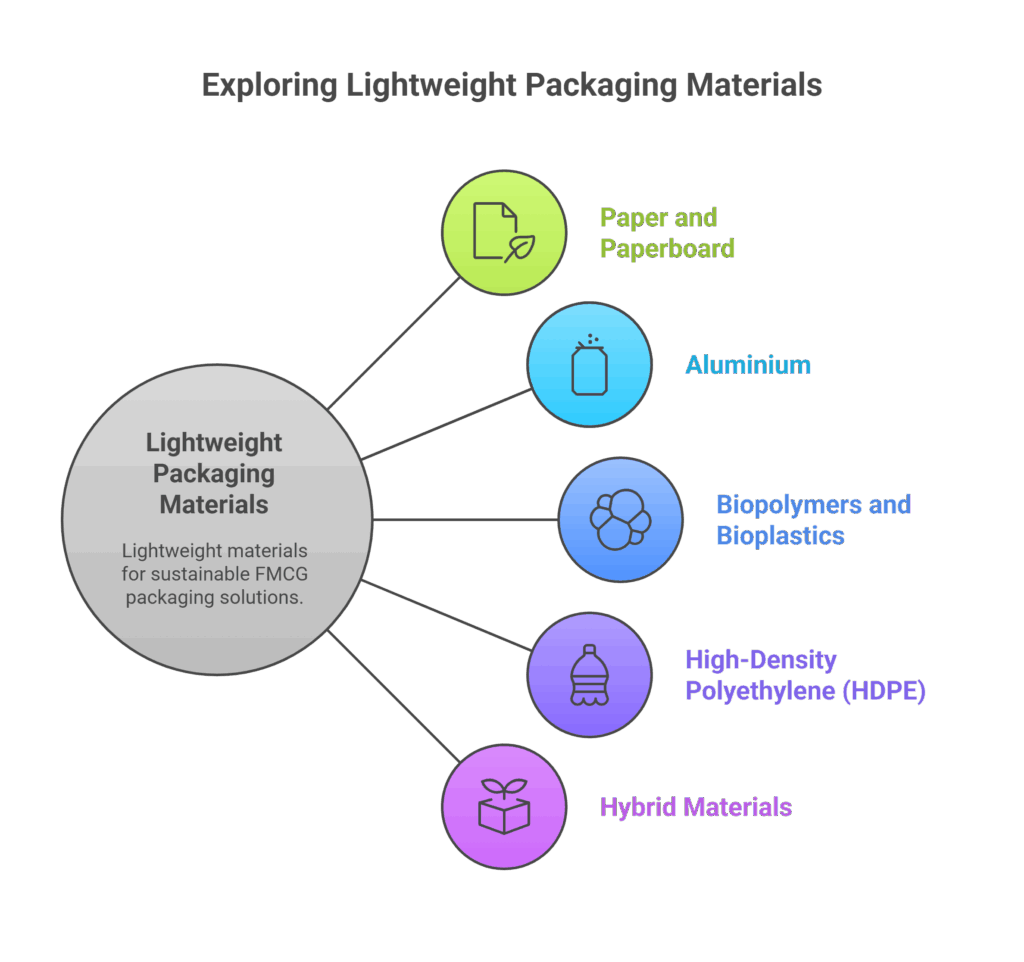

Types of Lightweight Materials Used in FMCG Packaging

A broad range of materials are available to use in lightweight FMCG packaging.

Paper and Paperboard: Paper, due to its lightweight properties and biodegradability, smartly replaces traditional steel and metal packaging. For secondary and tertiary packaging, corrugated cardboard is used, as it is acclaimed for its strength-to-weight ratio and the capacity to be recycled or sourced from renewable resources.

Aluminium: Aluminium combines protection against contaminants with relatively low weight and hence has become a leading lightweight packaging material. A practical example is that beverage cans have become thinner, yielding major cumulative savings in resources and emissions.

Biopolymers and Bioplastics: Natural biopolymers sourced from starch and protein and synthetic biopolymers like PLA (polylactic acid) are compostable and eco-friendly, unlike petroleum-based plastics that are non-biodegradable.

High-Density Polyethylene (HDPE): HDPE is increasingly being used in FMCG plastic bottles, as it is known for its strength, impact resistance, and lightweight nature, enhancing cost-effectiveness, and has a lower carbon footprint per unit.

Novel and Hybrid Materials: Mono-material packaging, which only uses a single material throughout, is becoming popular as it is easier to recycle. Mycelium-based and plant-based packaging is another way where agricultural waste and mushroom roots are harnessed for sustainable FMCG packaging.

Benefits of Lightweight Packaging for FMCG

When talking about the advantages of using lightweight materials for FMCG packaging, the environmental gains top the list. This is because lightweight packaging needs very few raw materials, which naturally minimises resource depletion. Besides this, lower shipping weights can cut fuel consumption and decrease CO₂ emissions. Studies suggest that the use of lightweight materials reduces carbon emissions by up to 20% when compared to traditional counterparts. Greater use of renewable, biodegradable, or compostable materials can also reduce landfill loads.

Economic savings is another important benefit, as reduced materials mean lower production costs. Shrinking packaging decreases shipping and delivery expenses while also lowering storage and handling costs. Use of lighter packaging materials also means less strain on machinery and faster throughput. This can significantly enhance production efficiency. Such kinds of packaging also show supply chain resilience; being easier to store and transport, they are less vulnerable to shocks.

Lighter and more ergonomic packaging can also enhance user efficiency, as it is convenient during transport and in end-user handling. Such packaging can be designed for easier grip, pouring, opening, and resealing, catering to consumer needs. This in turn improves customer satisfaction and brand loyalty. Using lightweight packaging materials helps companies meet regulatory mandates made by the government in terms of sustainability. This can positively influence corporate image, attract eco-conscious consumers, and open opportunities in new, sustainability-driven markets.

Innovation Strategies for Lightweight Sustainable FMCG Packaging

The design of the packaging is as important as the choice of materials in the lightweight packaging process. The use of finite element analysis, simulation, and automated production lines ensures that structures maintain durability with minimal material. Incorporation of ribs, corrugations, and strategically placed supports can maximise the durability with less bulk. Simple, mono-material packaging often looks premium and attracts consumers to the product while being easier to recycle. Cutting-edge design tools like digital simulation and 3D prototyping allow companies to fine-tune structural strength with minimal materials. Smart design introduces features like integrated handles, modular stacking, and resealability, all with a focus on weight reduction.

Active packaging (eg Oxygen scavengers) and intelligent packaging, which enables digital tracking, freshness monitoring, etc., can be incorporated with lightweight material packaging. This can further reduce unnecessary waste, increase shelf life, and please environmentally aware consumers. The use of AI and machine learning in packaging design optimises every gram of material, forecasting stress points and ensuring durability while keeping the weight minimum.

Conclusion

The popularity in the use of lightweight materials in FMCG packaging has risen not merely as a tactical shift, but it represents a broader, systemic transformation in how products are manufactured, transported, consumed, and disposed of. As companies today navigate rising production costs, consumer demand for sustainability and authenticity, and tightening regulations, lightweight packaging emerges both as a sustainability enabler and strategic differentiator.

As the use of lightweight materials in packaging gains momentum, it triggers more research, accelerating the discovery of breakthroughs like biodegradable nanomaterials and positive packaging. Leveraging digital twins, real-time life cycle analysis, and machine learning is needed to further enhance the applicability of the technique. But the success of lightweight sustainable FMCG packaging depends not just on material science but on collaborations across brands, suppliers, regulators, and recyclers.

Looking ahead, lightweight packaging aligns perfectly with the principles of a circular economy, as it not only changes individual product footprints but also drives systemic changes across supply chains, manufacturing strategies, and corporate sustainability agendas. Addressing the existing gaps in consumer perception, workforce training, and policy frameworks that prioritise material efficiency is needed to leverage the full potential of lightweight materials in FMCG packaging. But it is increasingly evident that what was once a packaging trend is fast becoming a business imperative, one that defines the next frontier of responsible FMCG innovation.