DS Smith has gone ahead and teamed up with Raymarine, which is a manufacturer of navigation systems as well as electronics for commercial marine along with the recreational boating sector, in order to create an alternative to the single-use plastic within the radar product line packaging of the company.

It is worth noting that Fibre-based corrugated cardboard materials are being used to replace the Expanded Polyethylene – EPE foam. DS Smith remarked that the solution can make sure that the radar products are offered with maximum protection against vibrations as well as unforeseeable physical impacts and also knocks at the time of transit as well as transportation.

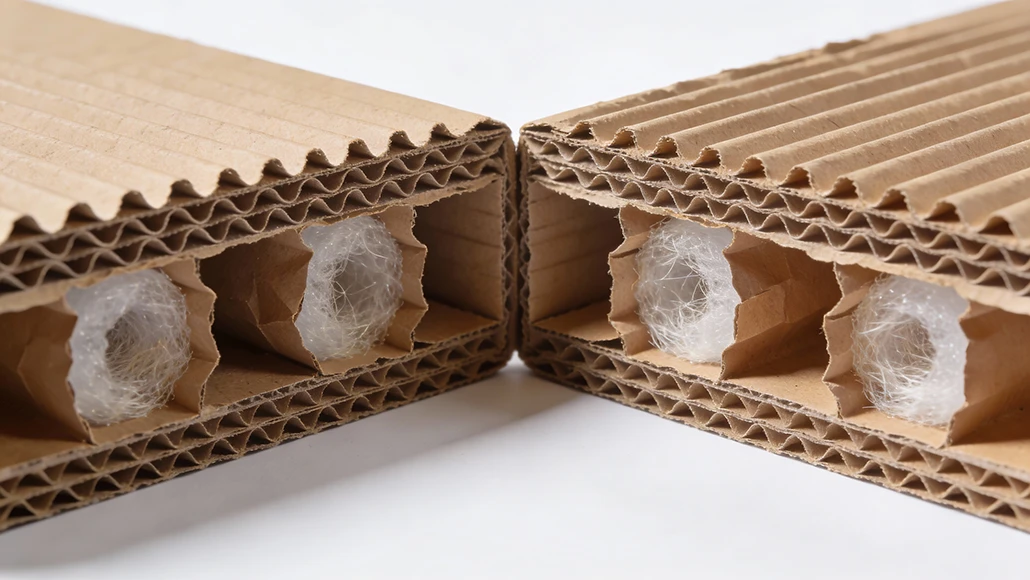

Apparently, a perpendicular-shaped corrugated cardboard flute having a 90-degree angle has been incorporated within the packaging structure so as to provide the built-in strength and also a reinforced capacity in order to withstand shocks. Crumple zone layers have been introduced to deform as well as absorb energy in the event of any kind of collision, while the fibre-based air cushions go on to offer that additional support.

DS Smith went on to add that the overall structure when it comes to the packaging goes on to contain accurately shaped corrugated cardboard inserts in order to make sure that Quantum radar products by Raymarine are being held securely in place at the time of any eventuality. Interestingly, the corrugated cardboard inserts are manufactured by way of using a folding technique, and within the design happens to be an additional integral box in order to package product accessories and also components separately.

Notably, the packaging can be made into an array of different sizes. The innovation is said to have eradicated plastic and also decreased the CO₂ emissions by more than 60% every year as compared to the previous packaging solutions offered by Raymarine.

DS Smith, Hungary’s cluster director, Levente Szabó, said that they are dedicated to enabling their customers in terms of finding new solutions when it comes to sustainable and circular-ready packaging. When evaluating a new packaging design, their process and development research considers the kind of materials that are used, in addition to production, transportation, and distribution, along with supply chain optimization. It is well to be noted that this packaging for Raymarine is made out of 84% recycled content as against 40% in previous packaging, and it is indeed 100% recyclable at the end of life. He went on to add that they have successfully gone on to replace EPE, and they can indeed go ahead and support manufacturers across both consumer and industrial sectors.

The VP of supply chain with Raymarine, Andrew Smith, added that one of their objectives is to eradicate single-use plastics from their packaging, and all thanks to their collaboration with DS Smith, they are making positive progress towards that objective.

The new packaging makes sure that products from their radar range are very well-protected at the time of transit while at the same time also meeting demands of the diverse climatic conditions along with long-haul international shipping. Smith added that they have retained agility within their production process in order to accommodate order volumes that are varied, and they are indeed proud of the visual impact of packaging, which is indeed clearly branded, recognizable in an instant, and also well-aligned with their core values.