Greif, a global leader in industrial packaging products and services, has partnered with CDF Corporation to introduce an innovative redesign of its GCUBE intermediate bulk container (IBC) Flex, engineered specifically for transporting highly sensitive and liquid products under sterile conditions.

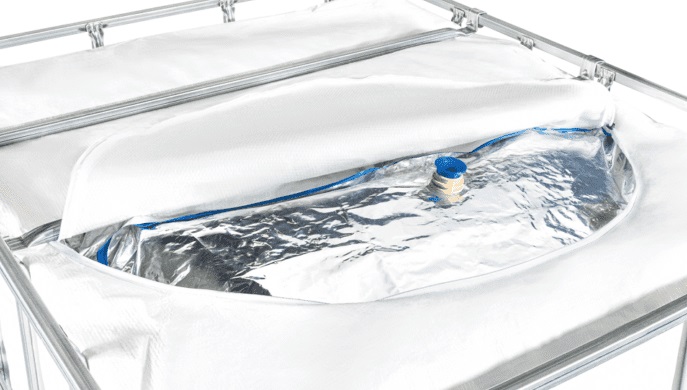

The next-generation GCUBE IBC Flex, available throughout the UK, Europe and Scandinavia, features an enhanced aseptic liner developed by CDF Corporation. The advanced Form-Fit™ liner outperforms conventional IBC liners, offering superior evacuation capabilities, and its unique design means it opens as a square to fit the internal shape of the IBC and fills automatically.

GCUBE IBC Flex is ideally suited for the food and beverage, flavours and fragrances, lubricants, and pharmaceuticals markets.

“We collaborated closely with CDF throughout the development process to ensure we delivered an upgraded product that meets the exacting needs of our customers. We needed to partner with an organisation like ours that prioritises sustainability at its core”, explained Jacob Demen, Sales Director Scandinavia from Greif. “Furthermore, our commitment to sustainability is reinforced by our collection and reuse or reconditioning of the entire GCUBE IBC Flex system, including the liner and outer structure, making it an ideal choice for closed-loop operations.”

David Khanna, Sales Director UK, added: “The launch aligns with our overarching innovation and investment strategy, which prioritises the development of sustainable solutions that not only enhance customer satisfaction but also uphold product integrity and safety,”

In a related development, CDF Corporation recently announced the opening of a new Form-Fit intermediate bulk container (IBC) liner manufacturing line in Germany, expanding their diverse liner offerings to assist with customers’ different needs.

GCUBE IBC Flex is currently manufactured in Sweden, the Netherlands, the UK, and Turkey, with capabilities within the United States coming in Q3 2024.