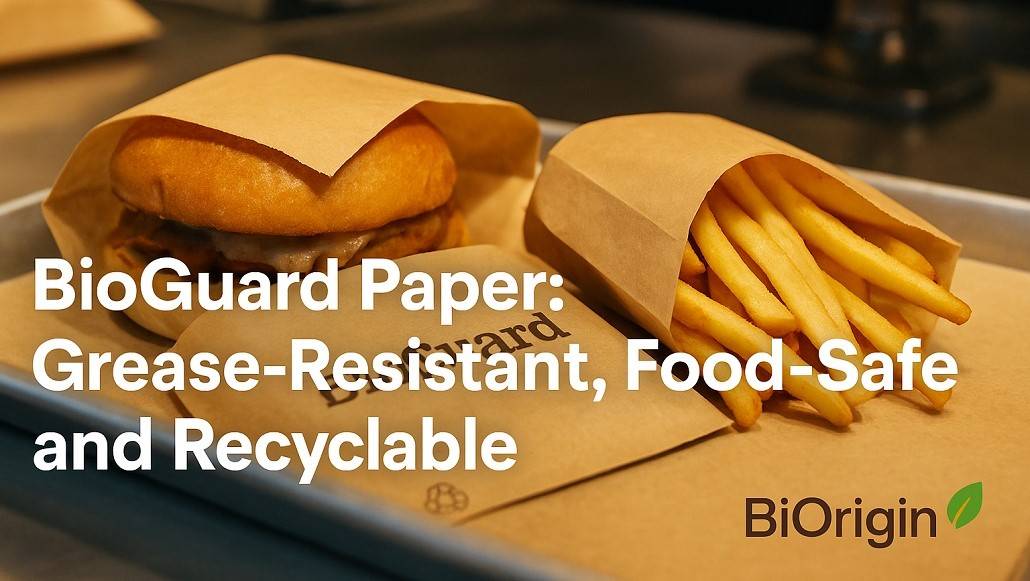

BiOrigin Speciality Products (BSP), a North American supplier of environmentally friendly speciality paper, has launched BioGuard paper, a new oil-and-grease-resistant (OGR) paper, to enhance foodservice packaging.

To prevent oil and grease from seeping through food bags and wrappers, the paper uses a 100% food-safe solution.

It is anticipated that the integration of BioGuard will increase the operating efficiency of OGR paper converters.

In comparison to competitors, the new paper has an improved reduction of visual staining in addition to its leakproof technology.

According to the company, the food-grade status of BioGuard also means that it will be recyclable.

With the utilisation of BSP’s Creative Solutions Network, which includes some of the mills in the US and Canada, the BioGuard paper will be manufactured in the US.

BiOrigin Specialty Products president and CEO Wade Kemnitz said: “We couldn’t be more excited to launch this innovative speciality paper for foodservice customers.

“The new food-safe formula greatly improves converting efficiency by eliminating the paper curling and cracking issues that occurs with other OGR solutions on the market today.

“Our BioGuard OGR paper is another sustainable solution from BSP that will provide an eco-friendly option for foodservice companies everywhere.”

BSP manufactures parent rolls for a variety of industries, including retail, medical, industrial, and foodservice.

It employs 600 employees, 100 of whom are Master Papermakers, and has a fleet of ten paper machines.

In October 2024, BSP installed a new Elite Cameron CS800 slitter rewinder at its Michigan mill, boosting its capacity by nearly half and increasing its rewinding capacity for the food packaging industry.

The CS800 machine uses the latest technology to ensure efficiency and security, such as photosensor light curtains and a shaftless pick-up unwind.