A global leader in specialty glass headquartered in Otsu, Japan, Nippon Electric Glass Co., Ltd. (NEG) has announced that it is going to begin the first mass production of pharmaceutical-grade glass tubing in the world by using an all-electric melting furnace. Its commercial production is scheduled to begin in December 2025 at its subsidiary located at Selangor in Malaysia.

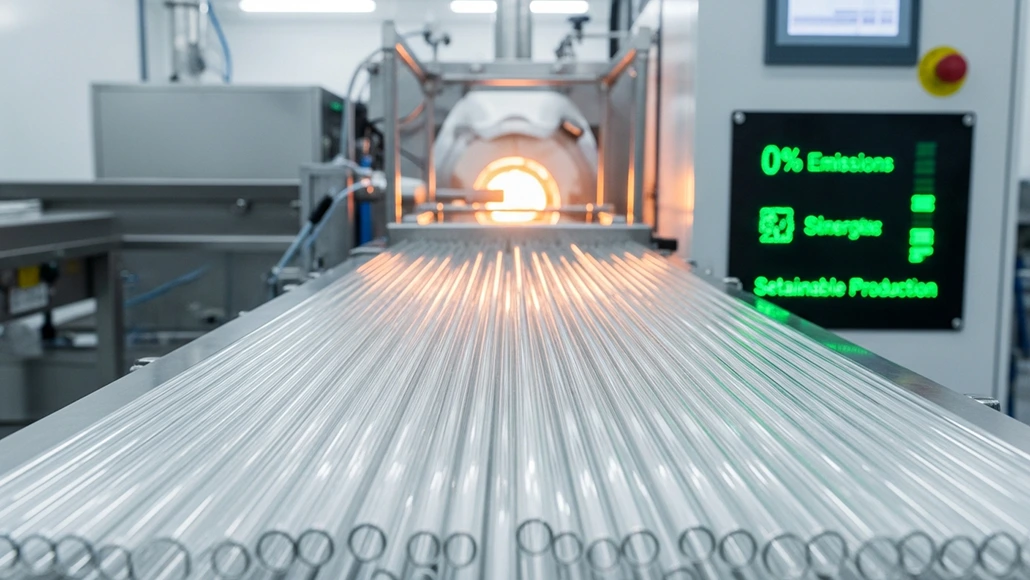

This breakthrough goes on to introduce a new manufacturing model when it comes to pharmaceutical packaging. Through combining the proprietary all-electric melting technology of NEG with renewable energy, CO₂ emissions that come from glass tubing production can very well get reduced by almost 90% as compared with the conventional fossil-fuel combustion furnaces.

This goes on to position NEG as a prominent supplier that is quite capable of delivering both high-performance borosilicate glass as well as a significantly lower carbon footprint, hence in a way directly addressing the global sustainability demands coming from pharmaceutical companies as well as regulators.

NEG, apparently, is a leading global supplier when it comes to arsenic-free, environmentally friendly borosilicate glass tubing made for medical containers, including the likes of vials, pre-filled syringes, and ampoules, as well as cartridges. Demand for such containers has seen a surge, which is driven by the global expansion of biopharmaceuticals. Specifically, markets in terms of GLP-1 formulations, the ones for diabetes and obesity treatments, are seeing a spike of almost 33% per year with growing demand across North America and Europe, along with emerging regions such as India and China. Through establishing this high-volume as well as low-emission manufacturing platform, NEG looks forward to supporting these fast-growing global requirements.

According to the vice president of NEG, Masamori Wada, launching the first mass production line when it comes to pharmaceutical-grade glass tubing in the world by way of using an all-electric furnace is indeed quite a major landmark, and they do see this as a rock-solid step toward carbon-neutral pharmaceutical supply chains, which helps customers to opt for products that are both high-grade as well as environmentally responsible.

A transition in how pharmaceutical glass gets made Traditional glass melting makes use of fossil fuels that generate large amounts of CO₂ as well as waste heat. The all-electric melting furnace by NEG makes use of its proprietary NEG Electric Melting Technology™ that applies electricity to get submerged electrodes to heat the glass directly. This goes on to attain high energy efficiency and eradicate combustion gas emissions as well as dramatically slash environmental effects while simultaneously maintaining high quality, which is needed for pharmaceutical glass.