Packaging lines today are faster, more diversified, and more automated than ever before. That’s great for volume. But it also creates new demands on how quality is maintained. Slight misalignments, temperature-driven changes in material behaviour, even dust all can impact the final product. Dependent solely on human checks or hard-coded rule-based systems is no longer sufficient.

That’s where machine learning comes in, not to take the place of human supervision but to augment it. It views things at scale, at velocity, and with recall. And best of all, it learns. This capacity to learn from experience, without being reprogrammed, is what’s establishing the new standard for packaging performance.

Machine learning in quality control provides something that classical systems can’t: flexibility. It learns from real packaging runs, spotting problem patterns and adapting to variations that fixed-parameter systems would miss.

Many packaging lines now use a blend of cameras, sensors, and software that together build a profile of what “good” looks like. From there, the system watches each unit passing down the line. It flags anything that falls outside the learnt profile, whether that’s a crooked label, a faint barcode, or a fill level that’s just a bit too low. And since it’s learning from real production, the system gets better and better.

This makes for a much more dynamic style of inspection. Instead of coding up new rules for each packaging change or product variation, teams can allow the system to naturally evolve.

Advantages of Machine Learning on Packaging Lines

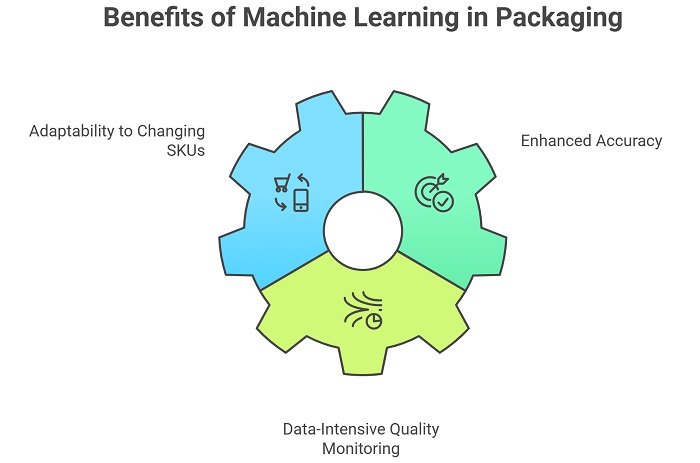

Copes with the fast-changing SKUs: For businesses having constant changes in products, the conventional inspection arrangements falter. Machine learning systems adapt rapidly, and hence they are perfect for changing lines.

Enhances accuracy over time: In contrast to static systems, these models learn more accurately the more they are exposed to. That translates into fewer false rejections and fewer failed products making it to the market.

Facilitates data-intensive quality monitoring: All decisions the system makes are tracked. This provides packaging teams with traceable quality information, valuable for audits, debugging, or ongoing improvement initiatives.

Through facilitating such intelligent inspection, machine learning provides companies with a means to increase quality control without increasing expenses. It also lays the groundwork for stronger supplier-customer trust, especially where brand integrity is closely tied to package presentation.

Real-World Uses

In the food and beverage sector, publicly available reports from safety agencies and trade groups have highlighted how automated vision systems enhanced by learning models are improving outcomes. From spotting sealing issues on dairy cartons to checking for underfilled beverage bottles, the application is broad and growing.

Pharmaceutical manufacturers are another early adopter. Machine learning helps check blister pack completeness, ensure batch numbers are printed correctly, and monitor for any deviation in shape or colour. Since many packaging issues in pharma are compliance-related, these systems also play a role in audit support. The European Medicines Agency has recognised the role of data-driven inspection tools in improving batch release integrity.

Even in heavier industries like industrial components or tools, packaging systems rely on visual accuracy. Labels need to be durable, barcodes must be clear, and packaging needs to remain protective. In these settings, machine learning ensures those expectations are met, even when packaging materials shift or product types vary widely between runs.

What It Takes to Implement Smart Quality Control

Rolling out machine learning in quality control isn’t a single-step job. It begins with data, images, or sensor readings collected from the line. These samples are then labelled to teach the system what passes and what doesn’t. Once trained, the model is deployed into the line, working alongside vision hardware to check live production.

Some facilities choose edge computing for speed. Here, decisions are made directly on the production floor, without the lag of cloud processing. Others opt for connected systems that integrate with broader factory analytics. Either way, the learning system becomes a part of the quality infrastructure.

Importantly, these tools don’t operate in isolation. They support technicians, floor managers, and quality engineers. When a defect pattern appears, the system flags it early, sometimes even tying it to specific machines or material changes upstream.

Standards, Oversight, and Industry Guidance

As machine learning in quality control becomes more widespread, global standards are catching up. Bodies like the International Organisation for Standardisation (ISO) and the European Committee for Standardization (CEN) are actively developing technical guidance on how AI systems should operate in manufacturing environments.

Among the areas being explored are explainability, transparency, and audit traceability. For packaging firms, particularly those working in regulated industries, this is a welcome development. It ensures that decisions made by algorithms can be shown, documented, and verified.

In practical terms, this means that when a shipment is flagged or a defect rate rises, the quality team isn’t left in the dark. The system provides visual records, timestamps, and explanations for why something was rejected. This not only streamlines audits but also strengthens supply chain transparency, especially when dealing with global partners.

Conclusion

In the packaging world where margins are tight and expectations are high, the kind of quiet reliability provided by Machine learning is priceless. It gives teams confidence. It gives clients reassurance. And it gives operations the kind of long-term consistency that’s hard to find anywhere else. For packaging professionals tasked with keeping production smooth and quality high, machine learning offers a toolset that’s as flexible as it is powerful. Not a replacement for good operators, but a partner in helping them do their job better.

It gives teams confidence in their process, knowing each unit is being tested fast and accurately. It gives customers confidence that their product is being packaged with care and accuracy, regardless of size or variety. And it gives operations long-term reliability that reduces waste, recall risk, and brand integrity.

As packaging becomes increasingly sophisticated, spurred by consumer expectations, environmental concerns, and tighter regulatory compliance, machine learning will not only be a value-add but also a minimum standard. For operators who want to future-proof their packaging lines, embedding machine learning in quality control is not merely a technology upgrade. It’s an operational bet on resilience, traceability, and enduring excellence. In an industry where the slightest detail can create customer trust, that quantum of intelligence is the difference between triumph and disaster.