The packaging sector is undergoing a structural correction. As supply chains face mounting pressure to adapt to environmental priorities, the question is no longer whether packaging should be recyclable, but how performance can be retained while simplifying the material structure. In this changing landscape, mono-material packaging is gaining ground, not as a sustainability gesture, but as a practical design strategy.

The idea of mono-material packaging is not new. What has changed is the industry’s ability to engineer it without trade-offs. Early approaches focused on reducing complexity at the cost of shelf stability, barrier strength, and process compatibility. But those limitations are no longer defining the format. Over time, the development of mono-materials has shifted from basic substitution to purposeful innovation. What now exists is a class of packaging materials that combine recoverability with resilience without relying on multi-layered, difficult-to-recycle constructions.

This is not a trend confined to a particular segment. From converters to brand owners, the move toward high-performance mono-material solutions is being driven by operational realism and long-term material accountability. These structures are being designed not only to survive the production line but also to remain compatible with recycling systems without the need for post-use disassembly or separation.

Replacing Laminate Complexity with Material Precision

Legacy packaging formats evolved in favour of multi-material laminates because each layer served a clear technical purpose. One controlled moisture, another provided strength, and a third enabled sealing or visual clarity. The result was packaging that worked under pressure but offered no path back into the system once discarded. With no shared material identity between layers, recyclability became theoretical.

Mono-material packaging offers a more disciplined approach. Rather than layering materials to solve problems one at a time, these structures rely on refinements within a single polymer group. The challenge has always been maintaining performance across the board—sealing, barrier, stiffness, and print performance—without introducing incompatibilities. That challenge is now being met through an evolving set of tools: orientation, blending, surface control, and careful formulation.

As these methods mature, mono-material formats are achieving the kind of structural and functional integrity previously reserved for composites. These materials behave consistently on packaging lines, withstand friction and load stress, and hold up in distribution, all while maintaining compatibility with mechanical recycling processes.

Operational and Strategic Drivers Behind the Shift

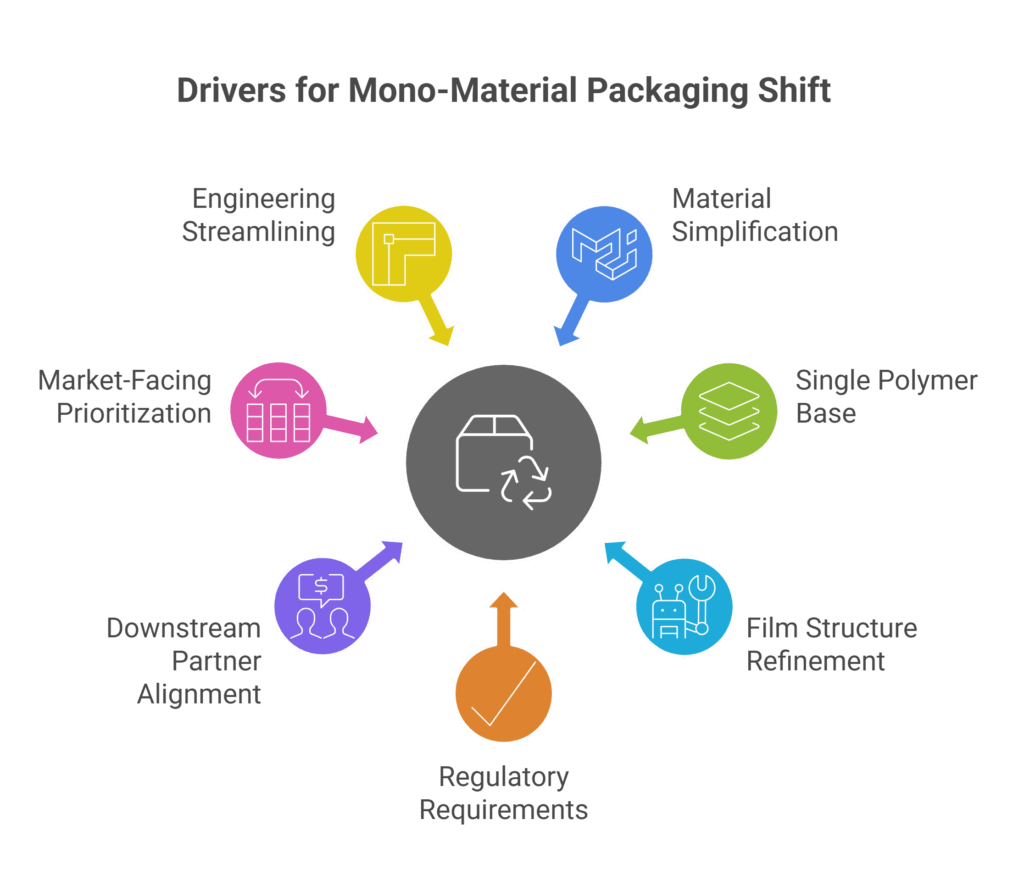

- Material simplification is improving clarity across design, procurement, and end-of-life handling.

- Packaging substrates built from a single polymer base are reducing reliance on complex laminate supply chains.

- Film structures are being refined to perform consistently across diverse product types and machinery platforms.

- Regulatory requirements are shaping internal packaging choices around recyclability and material accountability.

- Downstream partners are aligning capabilities with the processing of mono-polymer packaging formats.

- Market-facing teams are prioritising packaging that communicates responsible design without requiring interpretation.

- Engineering teams are streamlining development cycles by focusing on recoverable and compatible material groups.

Achieving Performance Within a Unified Material Identity

The structural strength of mono-material packaging lies in its coherence. What distinguishes high-performance solutions is not just that they use a single polymer family, but that every layer, function, and property has been tuned within that framework. It’s a more constrained design space, but one that yields more predictable results, especially in a circular economy context.

Orientation technologies have become central to this shift. Through mechanical stretching in specific directions, film properties such as tensile strength, puncture resistance, and sealability are enhanced without introducing additional polymers. Heat response and stiffness can be managed through layering strategies that remain within the same material group. These adjustments make mono-material films suitable for standard packaging formats—stand-up pouches, flow wraps, lids, and sachets—while retaining the flexibility required by modern manufacturing systems.

Surface treatments are also evolving. Rather than relying on metallised layers or cross-material coatings, engineers are adapting lacquers and barriers to remain within mono-material compliance. These films can now resist oxygen, moisture, and light exposure to a degree that meets packaging standards in sensitive applications.

Where once performance could only be achieved by stacking dissimilar layers, it is now being built into the molecular orientation, layering, and finishing of a single-material system. This is where high-performance mono-material packaging separates itself—not by removing function, but by redesigning how that function is delivered.

Business Considerations for Packaging Decision Makers

The movement toward mono-material packaging is also changing the internal calculus of packaging development. It encourages procurement to look beyond cost per tonne and evaluate alignment with longer-term material strategies. It compels R&D to factor in recyclability not as a benefit but as a starting point. And it pushes converters to build production capabilities that can support this shift without loss of efficiency.

Within business environments, the significance is compounded. Businesses do not just pass along packaging; they take responsibility for its design, execution, and end-of-life potential. Mono-material packaging reduces ambiguity. It offers a simpler answer when stakeholders ask how a package is meant to behave after use.

The consistency of using a single polymer group also reduces risk in certification, compliance checks, and customer communication. It creates fewer unknowns at the moment when packaging leaves the production floor and enters distribution. That clarity is increasingly valuable—not just in sustainability reporting but in operational planning.

Conclusion

When packaging design operates within tighter boundaries, creativity becomes more focused. Mono-material systems force the industry to think differently—not about what can be added to solve a problem, but what can be optimised within existing material capabilities.

This constraint does not limit progress; it sharpens it. It reduces the noise in development cycles and brings teams closer to the principles that now shape global material policies: traceability, recoverability, and design for re-entry. Where old formats relied on redundancy to achieve reliability, mono-material structures deliver results through precision.

What is now being adopted is not just a new packaging material but a new logic. One that sees performance and simplicity not as opposites, but as parts of the same objective. As that logic spreads, packaging solutions are becoming more robust in practice, more scalable in design, and more transparent in purpose.

Mono-material packaging may seem minimalist in form, but it reflects a considerable shift in how the industry builds resilience, not through addition, but through refinement.