The label-manufacturing business is evolving in its very heart as sustainability becomes a fundamental operational imperative and not a marketing add-on. The largest area of shift perhaps lies in the adhesives and inks utilised in label making. Previously neglected, these areas are now under the spotlight of innovation, with the makers wanting to align their operations based on environmental criteria, regulatory requirements, and consumer awareness on the rise.

Green adhesive and ink technology in label production is not simply about eco-friendly ingredients. It is a far-reaching approach to embracing materials that behave with reduced impact across the product life cycle. It is being driven by a combination of factors, including stricter rules, the need for responsible supply chains, and the ongoing goal of achieving a circular economy. As brands struggle to prove their green claims, packaging labels, the first physical contact with a consumer, are being redesigned from the ground up.

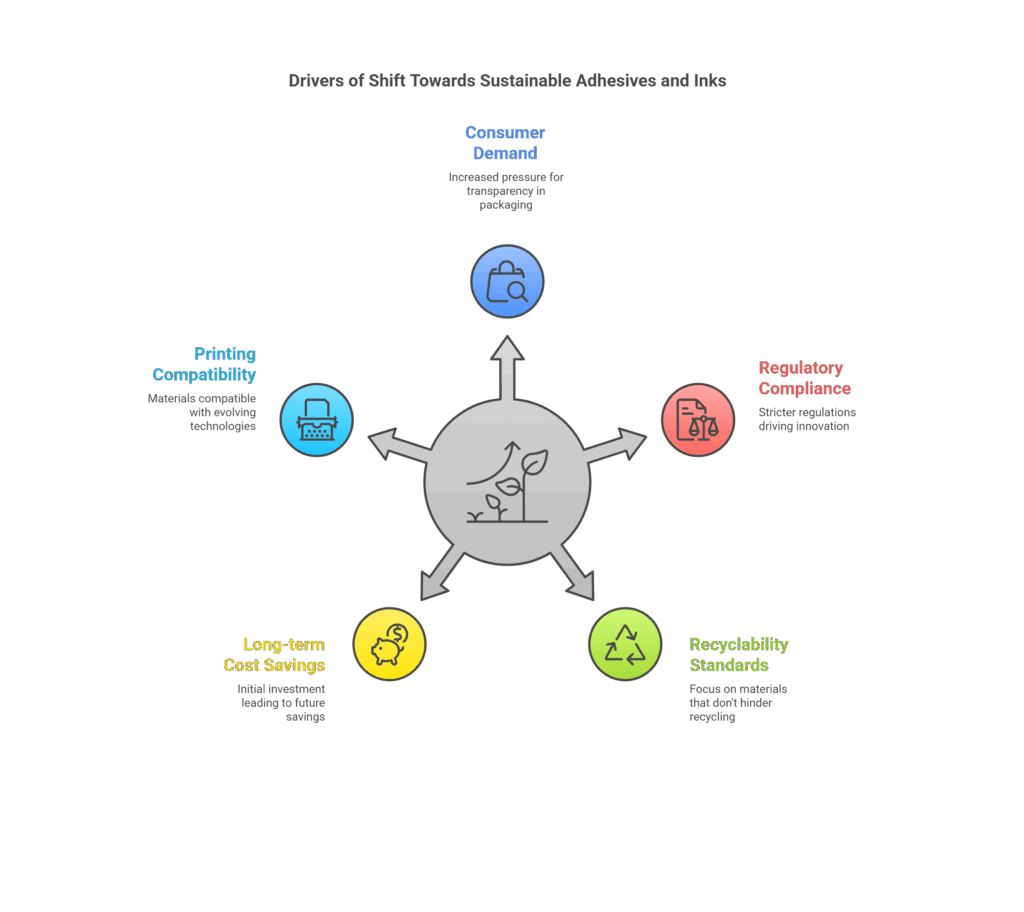

Key Drivers of the Shift to Sustainable Adhesives and Inks

- Consumer Demand for Transparency: Companies are under increasing pressure to show sustainability at every level, including in packaging elements like labels.┬Ā

- Regulatory Compliance: The EU Packaging and Packaging Waste Regulation (PPWR) and US FDA regulation are imposing greater requirements on ink toxicity and adhesive chemistry, with the latter being a key driver of fast innovation.

- Standards of Recyclability: The packaging must not interfere with mechanical recycling and composting. This is leading to wash-off design of adhesives and de-inkable products.

- Long-term Cost Savings: While new sustainable ink and adhesive technologies require more initial investment, the long-term cost savings of reduced waste and more efficient processes usually make the change worthwhile.

- Printing and Processing Compatibility: Printing technologies evolve, and with them, so must the materials that engage with them. Sustainable inks must be compatible with high-speed presses, and adhesives must preserve tack and peel strength amidst changing conditions.

Bio-Based and Water-Based Inks Redefining Label Printing

One of the most obvious sustainable adhesive and ink technologies employed in label production is increased utilisation of bio-based inks. It is obtained from renewable resources such as soybeans, linseed, and vegetable oils. These inks have much lower volatile organic compound (VOC) content than their traditional petroleum-based counterparts. Such a development reduces air pollution at both the point of production and consumption, while also reducing industry’s dependence upon non-renewable materials.┬Ā

Water-based inks are also making their mark, especially for uses where safety and removability are the highest priorities. They are being used in food and drug packaging, where low toxicity and regulatory acceptance are key. Aside from being healthier for human well-being, water-based inks produce cleaner print runs, reduced waste creation, and reduced equipment maintenance, all of which equate to more green production cycles.

Instead of seeing inks as make-up aids, producers are appreciating them as performance enhancers of a product’s sustainability appeal. Innovations in green ink and adhesive in label production are thus reshaping the boundaries of what a sustainable label can be as much as what a successful label can be.

Next-Gen Adhesive Technologies Enabling Circular Economy Targets

The adhesive segment of label production is changing fast with growing demand for recycling and composting. New pressure-sensitive adhesives (PSAs) are being developed, as they are easier to remove during recycling or break down in composting environments without leaving toxic residues. These improvements are the foundations for eco-friendly ink and adhesive technology in label production.

Wash-off adhesives, for instance, are making peeling of PET bottle labels simple in washing operations, maintaining material cleanliness. Compostable adhesives from natural polymers like starch or cellulose derivatives are being made to degrade with compostable films and papers, ensuring end-of-life compatibility.

Just as important are adhesives that interfere in the reprocessing of substrates. For recycled paper or cardboard, adhesives need to resist migration and can’t compromise de-inking systems. Today, manufacturers are doing their best to come up with products that work in harmony with recycling machinery. Integration of such technologies demonstrates how sustainable approaches in packaging label production are a part of larger packaging system objectives.

Sustainability Measurement and Label Manufacturing Compliance

Sustainability in the manufacturing of labels is no longer measured based on raw material procurement alone. It requires a full environmental footprint scan along the entire product life cycle.In this context, sustainable ink and adhesive technologies used in label manufacturing are being measured against a spectrum of performance metrics.

Sustainability standards like ISO 14001, Forest Stewardship Council (FSC), and Cradle to Cradle CertifiedŌäó are setting the new bar. European REACH regulation compliance and US EPA chemical use safety regulation compliance are no longer optionalŌĆöthey’re mandatory. The standards are influencing how manufacturers select every ingredient, from the resin systems in ink to solvents in adhesive bases.

Lifecycle assessment (LCA) methodologies are also enabling brands to quantify the environmental cost of their labelling choices. Supplier transparency regarding carbon footprint, water use, and post-consumer waste management is helping purchasing teams make more informed decisions. In this evolving mindset, sustainability is not abstract anymore; it is quantifiable, reportable, and increasingly regulable.

Future Outlook for Sustainable Approaches in Packaging Label Manufacturing

Although there is a clear market demand for eco-friendly ink and adhesive technology, the path to achieving it is not straightforward. The greatest challenge will likely be to sacrifice neither performance nor green credentials. Labels must continue to withstand UV radiation, abrasion, water, and temperature change, particularly when used in rugged applications such as logistics and food packaging. Obtaining such durability without reverting to previous synthetics or heavy metals means continuous formulation development and in-market trials.

Scalability is also an issue. Green adhesive and ink solutions have been commonly successful in pilot tests or small production runs, but consistency at industrial levels is an entirely different proposition. Availability of raw materials, supply chain volatility, and regulatory differences in geographical areas can all be obstacles in smoother adoption.

But the future is bright. Industry cooperation is taking centre stage, with converters, makers, and material experts working together on the creation and sale of new solutions. Collaborative partnerships between universities and industries are also driving innovation, particularly in bio-based chemistry and polymer chemistry. As sustainability becomes more deeply embedded in procurement practices and brand values, demand for more sustainable label elements will grow.

Industry also experiences increased R&D investments and infrastructure upgrades to enable sustainable ink and adhesive manufacturing in label production. They include changes in printing equipment, curing technologies, and storage units, completing a phased transition toward green manufacturing.

Conclusion

The transition to sustainable ink and adhesive technology in label production is a milestone for the packaging sector. It is a wake-up call that even the smallest component of a product ŌĆō its label, its adhesive, its colour ŌĆō is significant to the environment. Labels are not just carriers of information anymore. They are now an active participant in the transformation of a brand towards sustainability.

Such transformation demands technical efforts as well as systemic vision. It demands acknowledging the interconnections of ink formularies, glue science, recycling technology, and consumer activism. With increasing regulatory scrutiny and green awareness, businesses that commit themselves to sustainable labelling are better equipped to navigate the competition and compliance environments of the future.

Ultimately, sustainable approaches in packaging label manufacturing is not solely about cleaner products; there’s a need for the creation of a more responsible, transparent, and resilient packaging system.┬Ā