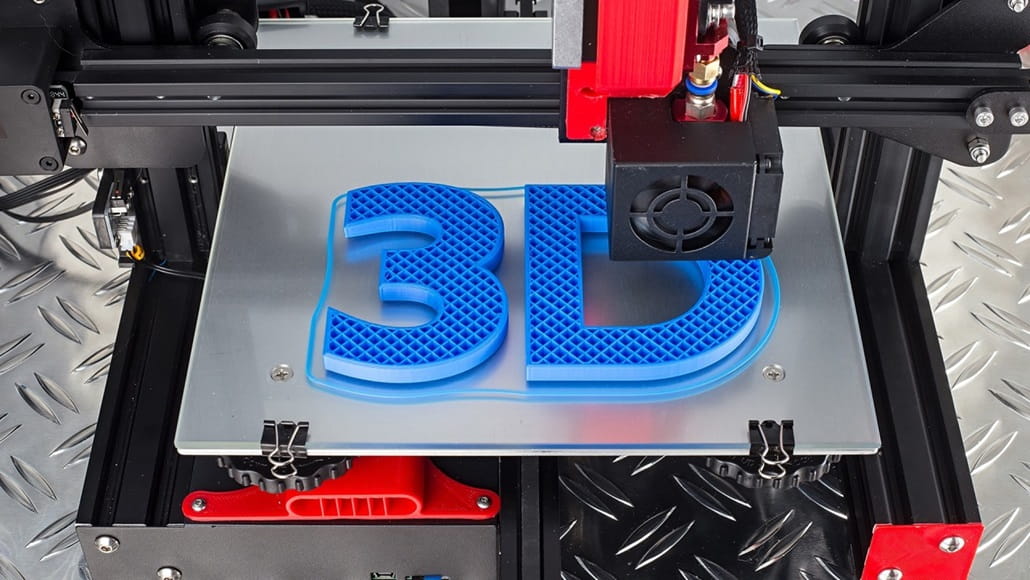

3D printing is revolutionizing the beauty industry by transforming the prototyping process for product development. Traditionally, creating prototypes of cosmetic packaging, applicators, or devices involved time-consuming and costly methods, such as injection molding or CNC machining. These processes often required multiple iterations to perfect the design, which could extend timelines and increase expenses. However, with the advent of 3D printing, beauty brands now have the ability to rapidly produce highly detailed prototypes at a fraction of the cost and time.

Speed and Efficiency in Prototyping

One of the key advantages of 3D printing is the speed at which prototypes can be produced. In just hours, a physical model can be created from a digital file, allowing for faster testing and evaluation. This agility is particularly valuable in the fast-paced beauty industry, where trends change quickly, and time-to-market is critical. By accelerating the prototyping phase, beauty brands can bring products to market faster, keeping ahead of competitors.

Creative Freedom and Flexibility in Design

3D printing offers unparalleled design freedom. Unlike traditional methods, which may have limitations based on tooling or manufacturing processes, 3D printing allows for complex geometries, intricate details, and innovative textures. This flexibility enables designers to push the boundaries of creativity, experimenting with shapes, sizes, and textures that would be difficult or impossible to achieve using conventional methods. Whether it’s a custom lipstick mold with intricate engraving, an ergonomic skincare applicator with a unique texture, or an innovative perfume bottle with an unconventional shape, 3D printing gives beauty brands the freedom to explore new possibilities.

Sustainable Development and Reduced Waste

Another significant benefit of 3D printing is its potential to reduce waste during the development phase. Traditional prototyping often involves multiple iterations, leading to discarded materials and excess waste. In contrast, 3D printing allows for precise material usage, meaning that only the required amount of material is used to create each prototype. This reduces overall waste and contributes to more sustainable product development processes. Additionally, the ability to test designs before committing to mass production helps brands avoid costly production errors and reduce waste in the final product.

Customization and Personalization

The beauty industry is increasingly moving towards personalization, with consumers seeking products tailored to their unique needs. 3D printing enables beauty brands to create personalized products with ease. From custom-fit makeup applicators to packaging designed for specific consumer preferences, 3D printing allows for the production of one-off or limited-run items that cater to individual needs. This ability to create bespoke products not only enhances the consumer experience but also strengthens brand loyalty by offering unique, tailored solutions.

Future of 3D Printing in Beauty Packaging

As 3D printing technology continues to advance, its role in beauty packaging is likely to expand. Future developments may include the use of more sustainable materials, such as biodegradable or recyclable plastics, which would align with the industry’s increasing focus on sustainability. Furthermore, advancements in multi-material printing could enable the creation of prototypes that more closely mimic the final product, allowing for more accurate testing and evaluation of functionality, durability, and aesthetics.

APC Packaging: Your Partner in Innovation

Looking to create something truly unique? Contact the APC Packaging team to discuss how you can develop a one-of-a-kind packaging solution for your brand. APC has heavily invested in its 3D capabilities and is ready to assist its partners in the development of innovative, sustainable, and personalized packaging solutions. Whether you’re looking to test new designs or bring innovative products to market faster, APC Packaging can help turn your vision into reality. [Contact Us Today]to learn more about how 3D printing can revolutionize your packaging development process.

By leveraging 3D printing, beauty brands can innovate faster, reduce waste, and create the personalized, sustainable solutions that today’s consumers demand.