The Transformative Impact of AI-Powered Packaging Software on Modern Production

In the high-velocity world of modern global manufacturing, the margin for error is shrinking to near-zero as consumer expectations and regulatory requirements continue to climb. As brands compete for consumer trust in an increasingly crowded and transparent marketplace, the physical package has become a primary and critical touchpoint for quality assurance and brand integrity. The emergence of AI-powered packaging software represents perhaps the most significant advancement in industrial quality control since the initial introduction of the assembly line. By replacing subjective, fatigue-prone human inspection with objective, lightning-fast, data-driven analysis, these systems are enabling a level of manufacturing precision and consistency that was previously considered technically unattainable. This digital revolution is not just about catching mistakes after they happen; it is about building an intelligent, autonomous production environment that actively learns, adapts, and improves with every single package it processes.

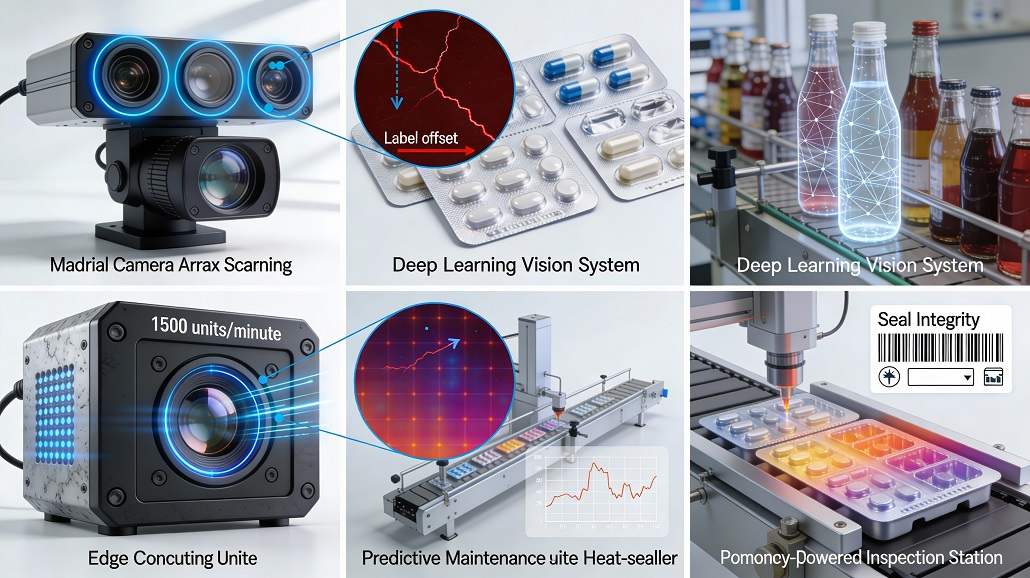

The Evolution from Visual Inspection to Advanced Computer Vision

Traditional packaging quality control has historically relied heavily on human operators or basic, rule-based sensor systems that checked for simple presence or absence. However, these methods are severely limited by human fatigue, cognitive bias, and the inherent inability of traditional sensors to understand complex, non-linear patterns. AI-powered packaging software utilizes advanced computer vision a powerful subset of artificial intelligence that allows machines to “see,” interpret, and understand visual data in a way that mimics and then surpasses the human brain. These systems are trained on massive datasets containing millions of images of both “perfect” and “defective” packages, allowing them to identify incredibly subtle issues such as micro-cracks in glass containers, improper cap torque, or minute color deviations in complex branding. Because the software uses deep learning neural networks, it becomes more accurate and sophisticated over time, constantly refining its internal model of what constitutes a truly high-quality product.

Enhancing Operational Efficiency Through Predictive Analytics

One of the most powerful and commercially valuable features of modern AI-powered packaging software is its ability to move beyond the “here and now.” While real-time defect inspection is absolutely vital for current production, the true long-term value of AI in the packaging industry lies in its advanced predictive capabilities. By monitoring the performance and vibrations of every motor, belt, and sealer on the production line, the software can identify the incredibly early warning signs of mechanical wear and tear that are invisible to human maintenance teams. For example, if a heat sealer begins to fluctuate in temperature by even a fraction of a degree, or if a vacuum pump shows a slight change in its cycle, the AI can flag this as a potential source of future leaks or failures. This allows plant managers to intervene with scheduled maintenance before a single defective package is ever produced, shifting the operational paradigm from “fixing errors” to “preventing them entirely.”

Real-Time Packaging Inspection at Industrial Speeds

The fundamental challenge for any quality control system is maintaining absolute accuracy without slowing down the primary production line. Modern AI-powered packaging software is specifically designed to operate at the extreme, high-volume speeds common in the beverage and pharmaceutical industries, where lines often run at well over 1,000 to 1,500 units per minute. Using high-performance GPU (Graphics Processing Unit) processing and edge computing, the AI can analyze multiple angles of a package simultaneously, verify the barcode and serialization, check the precise fill level, and confirm the hermetic seal integrity in a fraction of a second. These high-speed automated inspection systems ensure that throughput is never compromised for the sake of quality, allowing global manufacturers to maximize their total output while maintaining a strict and reliable “zero-defect” policy that protects their brand and their bottom line.

Reducing Waste and Improving Sustainability with Smart Analytics

In the current global climate, sustainability is no longer an optional or “nice-to-have” goal for manufacturers; it is a core business requirement and a consumer expectation. AI-powered packaging software plays a critical and growing role in reducing the environmental footprint of a manufacturing facility. By catching defects at the very beginning of the production line such as a slightly misaligned label or a dented empty bottle—the system can prevent the further waste of the valuable food or liquid product itself. Furthermore, smart packaging analytics can identify “over-packaging” trends or inefficiencies, where a machine might be consistently using more adhesive, film, or energy than is strictly necessary to achieve a secure and safe seal. By optimizing these minute parameters across millions of units, the AI helps the company significantly reduce its total raw material consumption and lower its energy usage, effectively aligning operational excellence with environmental stewardship.

The Role of AI in Regulatory Compliance and Public Safety

In highly regulated and sensitive industries like food, beverage, and pharmaceuticals, quality control is not just a brand preference; it is a matter of strict legal compliance and critical public safety. AI-powered packaging software provides a comprehensive, permanent digital “audit trail” for every single unit produced. If a safety issue or contamination is discovered later in the complex global supply chain, the manufacturer can use the granular data stored in the AI system to pinpoint exactly when, where, and why the problem occurred, allowing for a targeted and limited recall rather than a broad, expensive, and damaging one. This level of visibility is essential for meeting the increasingly stringent requirements of global organizations like the FDA and the WHO. Moreover, the software can ensure that mandatory safety information, such as allergen warnings, dosage instructions, or expiration dates, is not only present but perfectly legible, protecting both the consumer and the brand from the legal and health ramifications of labeling errors.

Future Outlook: The Rise of the Autonomous Packaging Facility

As we look toward the future of the industry, the integration of AI-powered packaging software is the first and most crucial step toward the realization of the fully autonomous “Dark Factory” a facility that can operate with minimal human intervention. In this sophisticated scenario, the AI doesn’t just flag errors for human review; it makes real-time, autonomous adjustments to the machinery to correct the issue on the fly. If the software detects that labels are trending toward the left edge of the bottle, it can communicate directly with the labeling machine’s servo-motors to instantly recalibrate the applicator position. This closed-loop system represents the pinnacle of the Industry 4.0 revolution, where human workers are moved from repetitive, physically demanding inspection tasks to higher-level strategic, creative, and technical roles. By embracing these intelligent systems, the packaging industry is ensuring that it remains resilient, efficient, and capable of meeting the complex, rapidly shifting demands of the 21st-century global consumer.

AI and the Customization of Packaging

Another burgeoning area for AI in the packaging industry is mass-customization. Consumers are increasingly demanding products that feel personalized, which usually means short production runs with frequent changes in labels and packaging designs. Traditionally, these “changeovers” are the enemy of efficiency, requiring hours of manual recalibration. However, AI-powered software can recognize new designs instantly and automatically adjust the inspection parameters to suit the new product. This allows manufacturers to offer a much wider variety of SKUs (Stock Keeping Units) without a significant drop in productivity. The software can even check for language-specific nuances on labels intended for different global markets, ensuring that a product destined for Tokyo has the correct Japanese characters, while the same product destined for Paris has the correct French text. This flexibility is a key driver for the growth of personalized consumer goods and regionalized pharmaceutical products.

Conclusion: The AI Advantage

In summary, the transition to AI-powered packaging software is a fundamental reimagining of what is possible in a production environment. It provides the perfect balance of speed, accuracy, and intelligence that modern manufacturing demands. For brands, the benefit is clear: fewer recalls, higher quality, and a deeper understanding of their own production processes. For consumers, it means safer products and more reliable information. As artificial intelligence continues to evolve, its footprint in the packaging industry will only grow, paving the way for a more efficient and trustworthy global economy. The era of the “smart” line is no longer a futuristic dream; it is the current reality for the world’s leading manufacturers, and AI is the engine driving it forward.