In an age where environmental sustainability along with stability happens to be paramount, plastic materials recycling has gone on to become a very crucial focal point for manufacturers, researchers, and also policymakers.

Among the numerous kinds of plastics, polyethylene terephthalate – PET, as well as polyethylene – PE multilayer packaging materials are commonly used because of their strength as well as versatility. But the efficient recycling of PET-PE multilayer packaging materials goes on to present a very prominent challenge because of their complex structure as well as their inherent issues when it comes to separation. In this regard, the innovative approach of enzymatic depolymerization of PET goes on to emerge as a very promising solution for efficient recycling of PET-PE multilayer packaging materials.

Let’s know the PET-PE multilayer packaging materials more

PET-PE multi-packaging materials happen to be broadly used in the food and beverage industry because of their excellent barrier properties, which help protect the products from light, moisture, and air. These materials are often found within flexible packaging like bottles and pouches, thereby offering a mix of durability along with lightweight convenience. As per a report by Smithers Pira, the worldwide flexible packaging market is anticipated to touch almost $300 billion by 2024, thereby scoring the continued dependence on these materials. In spite of their practicality, the environmental effect of PET-PE multi-packaging cannot be given a plain look. The usage of multiple layers happens to complicate the recycling processes since the traditional methods often struggle to separate varied materials in an effective way. Due to this, a prominent part of these multiplayer packages happens to end up in incinerators or landfills, thereby contributing to the rising plastic waste crisis.

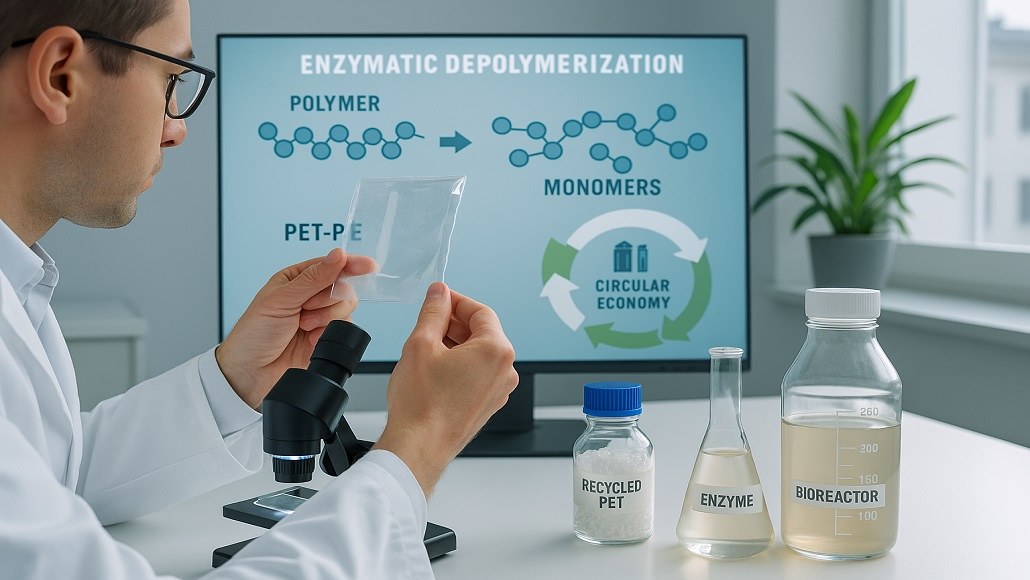

The role when it comes to enzymatic depolymerization within recycling

There are recent advancements in biochemistry that have paved the way for more effective recycling methods, especially enzymatic depolymerization. This kind of process happens to involve making use of specific enzymes in order to break down the polymer chain of PET into their constituent monomers, which can then get reversed in order to produce novel PET materials. This research underscored in the ACS Sustainable Chemistry and Engineering journal highlights the effectiveness when it comes to enzymatic methods as far as achieving high yields of pure recycled PET is concerned. Enzymatic depolymerization goes on to offer numerous advantages as compared to traditional physical as well as chemical recycling methods.

First, it functions at mild reaction conditions, which goes on to conserve energy and also maximize the environmental footprint. Second, the enzymatic process goes on to showcase high specialty, thereby decreasing the risk as far as contamination and making sure that the quality of the recycled output gets maintained. As per the findings published in the ACS Journal, the usage of engineering enzymes can lead to a depolymerization efficiency of almost 90%, thereby making it a very highly effective method in terms of addressing the issues of efficient recycling of PET-PE multiplayer packaging materials that are based on enzymatic depolymerization of PET.

What are the technological innovations in enzyme engineering?

The success when it comes to enzymatic depolymerization depends heavily on advancements in enzyme engineering. The research has gone on to show that by way of optimizing the structure as well as the activity of PET-degrading enzymes, the researchers can elevate their performance in terms of breaking down complex PET-PE multi-packaging materials. For example, the usage of microbial enzymes, which are derived from bacteria and fungi, has demonstrated incredible efficacy in terms of catalyzing the depolymerization process. One notable enzyme happens to be PETase, which was discovered in the bacterium Ideonella sakaiensis.

The enzyme has gone on to show an incredible capacity to degrade PET under ambient scenarios, thereby making it an ideal candidate as far as recycling applications are concerned. Researchers have since then engineered a PETase variant to grow its balance and activity, thereby further enhancing the efficiency in terms of the depolymerization process.

What are the economic and environmental applications?

The efficient recycling of PET-PE multilayer packaging materials, which is based on enzymatic depolymerization of PET, is not just an academic exercise. It happens to have real-world implications when it comes to both the economy and the environment. By way of embracing enzymatic recycling techniques and technologies, the packaging industry can prominently decrease its dependence on virgin plastics and also decrease the production costs that are associated with raw material procurement.

Besides this, the environmental advantages associated with enzymatic recycling are enough. By diverting pet-pe multiplayer packaging from landfills as well as incinerators, companies can, in a way, substantially reduce greenhouse gas emissions as well as fossil fuel consumption. As per a life cycle assessment that was conducted by the authors of the ACS study, enzymatic recycling can also lead to a decrease of almost 70% in terms of carbon emissions as compared to traditional recycling methods.

Barriers as well as future directions

In spite of the promising outcomes, the path when it comes to widespread adoption of enzymatic depolymerization in terms of recycling PET-PE multilayer packaging materials is not without any kind of challenges. One of the primary barriers is the requirement for large-scale enzyme production as well as associated costs. While the laboratory-scale experiments have gone on to yield impressive results, the scaling of these processes when it comes to industrial applications still remains a significant undertaking.

Besides this, further research is required in order to develop enzymes that are capable of efficiently depolymerizing intricate multilayer structures. Innovation within enzyme screening as well as high-throughput screening methods is necessary in order to identify as well as optimize the novel candidates that can tackle other kinds of plastics in addition to PET.

Moreover, coming up with a circular economy for plastics is going to require partnership between researchers, policymakers, and manufacturers. Regulation as well as incentives that happen to promote recycling and the usage of recycled material can prominently catalyze the enzymatic recycling method adoption.

Conclusion

Finally, the efficient recycling of PET-PE multilayer packaging materials, which is based on enzymatic depolymerization of PET, happens to represent a prominent advancement in the quest for sustainable waste management solutions. With the capacity to convert plastic waste back into valuable resources by way of innovative and automatic processes, the potential in terms of a circular economy within the packaging industry goes on to become increasingly attainable. As the research continues to evolve and enzyme technologies go on to advance, the prospects for enzymatic depolymerization are indeed very promising. By way of harnessing the power of technology and executing effective recycling strategies, one can indeed pave the way for a future that is very sustainable in the spectrum of packaging and also, in a way, decrease the environmental effect of plastic waste on the planet.