The modern packaging industry stands at the threshold of a technological revolution that promises to reshape manufacturing operations fundamentally. As global demand intensifies and supply chains become increasingly complex, packaging automation emerges as the critical solution for businesses seeking to maintain competitive advantage while achieving operational excellence. This transformation represents far more than simple mechanization; it embodies a comprehensive reimagining of how products move from production lines to consumer hands.

Manufacturing facilities worldwide are witnessing unprecedented pressure to deliver higher volumes, maintain consistent quality, and reduce operational costs simultaneously. Traditional manual packaging processes, once adequate for simpler market conditions, now struggle to meet the demands of modern commerce. The integration of sophisticated robotic systems, intelligent sensors, and adaptive control mechanisms has created opportunities for manufacturers to transcend these limitations while establishing new benchmarks for efficiency and reliability.

The financial implications of this technological shift extend beyond immediate cost savings. Companies implementing comprehensive packaging automation strategies report substantial improvements in worker safety, reduced product damage rates, and enhanced ability to respond rapidly to changing market demands. These benefits compound over time, creating sustainable competitive advantages that prove difficult for competitors relying on traditional methods to match.

Robotic Technologies Reshaping Packaging Operations

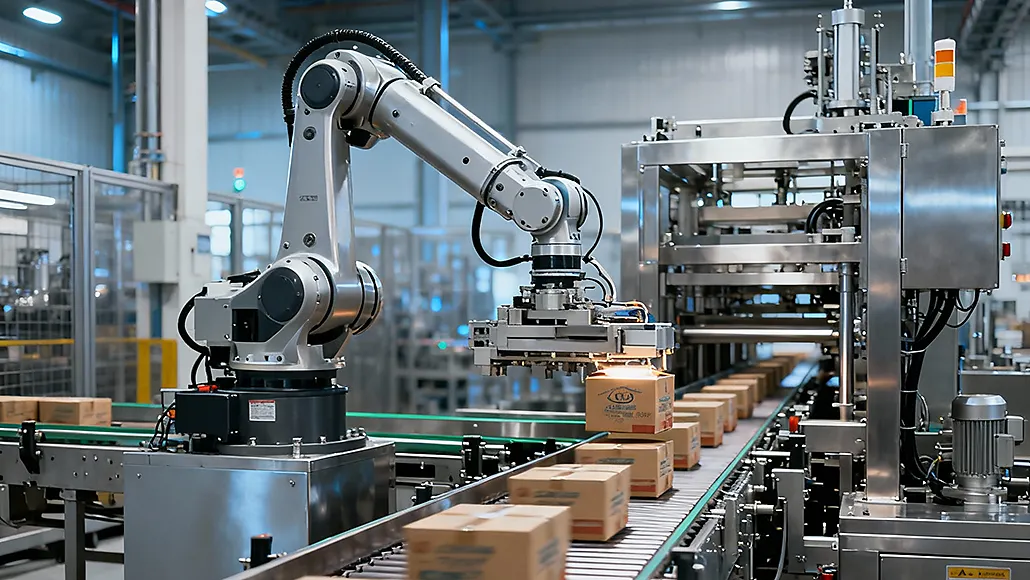

The landscape of robotic packaging has evolved dramatically from the rigid, programmed systems of previous decades to today’s adaptive, intelligent machines capable of handling complex tasks with remarkable precision. Modern robotic packaging systems incorporate advanced vision systems, machine learning algorithms, and sophisticated end-effectors that enable them to manage diverse product types without extensive reprogramming.

Delta robots represent one of the most significant advances in high-speed packaging applications. These systems can achieve picking rates exceeding 120 items per minute while maintaining exceptional accuracy across various product sizes and shapes[7]. Their compact design allows integration into existing production lines without requiring extensive facility modifications, making them particularly attractive for manufacturers seeking to upgrade operations incrementally.

Articulated robotic arms have found extensive application in secondary packaging operations, where their flexibility proves invaluable for case packing, palletizing, and quality inspection tasks. These systems demonstrate remarkable adaptability, capable of switching between different packaging formats with minimal downtime. Advanced gripper technologies, including vacuum systems, magnetic grippers, and adaptive mechanical fingers, enable these robots to handle products ranging from delicate electronics to heavy industrial components[2].

The integration of artificial intelligence into robotic packaging systems has created unprecedented capabilities for real-time decision making and process optimization. Vision-enabled robots can now identify product defects, verify proper placement, and adjust their movements based on environmental conditions. This intelligence extends to predictive maintenance capabilities, where robots monitor their own performance and schedule maintenance activities to prevent unexpected failures[8].

Collaborative robots, or cobots, have introduced new possibilities for human-robot cooperation in packaging environments. These systems work safely alongside human operators, combining the precision and endurance of automation with human flexibility and problem-solving capabilities. Cobots excel in applications requiring frequent changeovers or handling of irregular products that might challenge fully automated systems.

Smart Systems Revolutionizing Packaging Efficiency

The convergence of Internet of Things technologies, cloud computing, and advanced analytics has created smart packaging systems that operate with unprecedented sophistication. These interconnected networks transform individual machines into components of larger, intelligent manufacturing ecosystems capable of self-optimization and predictive performance management.

Real-time monitoring systems collect data from every aspect of packaging operations, creating comprehensive visibility into production performance, quality metrics, and equipment status. This information enables managers to identify bottlenecks, predict maintenance requirements, and optimize production schedules based on actual demand patterns rather than historical estimates[22]. The result is dramatically improved overall equipment effectiveness and reduced unplanned downtime.

Machine learning algorithms analyze historical performance data to identify patterns and optimize packaging parameters automatically. These systems continuously refine their operations, adjusting variables such as speed, pressure, and timing to maximize throughput while maintaining quality standards. Some implementations have achieved efficiency improvements exceeding 30% through intelligent optimization of packaging line parameters[1].

Integration with enterprise resource planning systems enables smart packaging lines to respond dynamically to production schedules, inventory levels, and customer requirements. This connectivity ensures that packaging operations align perfectly with broader manufacturing objectives while minimizing waste and maximizing resource utilization[25].

Quality management systems embedded within smart packaging operations provide real-time feedback on product consistency, packaging integrity, and compliance with regulatory requirements. Advanced vision systems can detect defects invisible to human inspectors while maintaining production speeds that would be impossible with manual quality control processes.

Strategic Cost Reduction Through Advanced Automation

The financial benefits of packaging automation extend far beyond simple labor cost reductions, encompassing improvements in material utilization, energy efficiency, and overall operational effectiveness. Companies implementing comprehensive automation strategies typically recover their investments within 18 to 36 months while establishing foundations for long-term cost advantages[6].

Labor cost optimization represents the most visible benefit of packaging automation, with some implementations reducing workforce requirements by 60% or more while increasing output substantially[6]. However, the strategic value extends to workforce redeployment, where companies redirect human resources toward higher-value activities such as quality management, process improvement, and customer service.

Material waste reduction through precision packaging systems generates significant ongoing savings. Automated systems can reduce packaging material consumption by 15-25% through optimized application of films, adhesives, and protective materials[3]. This precision extends to product handling, where robotic systems minimize damage rates that typically plague manual operations.

Energy efficiency improvements in modern packaging automation systems contribute substantially to operational cost reductions. Advanced servo motor technologies, regenerative braking systems, and intelligent power management can reduce energy consumption by 30-40% compared to traditional pneumatic systems[4]. These improvements become increasingly valuable as energy costs continue rising globally.

Maintenance cost optimization through predictive maintenance programs enabled by intelligent packaging systems prevents costly unplanned downtime while extending equipment lifecycles. Systems that monitor their own performance can schedule maintenance activities during planned production breaks, avoiding disruptions that typically cost manufacturers thousands of dollars per hour[31].

Future Developments in Automated Packaging

The trajectory of packaging automation points toward increasingly sophisticated systems that will further transform manufacturing operations over the coming decade. Emerging technologies promise to address current limitations while creating entirely new capabilities that will redefine packaging possibilities.

Artificial intelligence integration will evolve beyond current pattern recognition and optimization applications to encompass comprehensive autonomous decision-making capabilities. Future packaging systems will manage complex production scenarios, adapt to unexpected situations, and optimize operations across multiple variables simultaneously without human intervention[1].

Flexible automation systems designed for rapid reconfiguration will enable manufacturers to respond instantly to changing product requirements or market conditions. Modular robotic systems that can be recombined into different configurations within hours rather than days will provide unprecedented agility for companies serving dynamic markets[8].

Sustainability integration will become a fundamental aspect of packaging automation, with systems designed to minimize environmental impact through optimized material usage, energy efficiency, and integration with circular economy principles. Advanced packaging automation will automatically select optimal packaging configurations based on environmental impact metrics alongside traditional efficiency considerations.

Human-machine collaboration will evolve to create seamless partnerships where human creativity and problem-solving capabilities combine with robotic precision and endurance. These collaborative systems will adapt their behavior based on human preferences and working patterns while maintaining optimal productivity levels.

The integration of blockchain and distributed ledger technologies will create transparent, traceable packaging operations where every aspect of the packaging process is recorded and verified. This capability will prove essential for industries requiring rigorous quality documentation and regulatory compliance while enabling new business models based on packaging performance guarantees.

Advanced sensor technologies including hyperspectral imaging, ultrasonic inspection, and chemical sensors will enable packaging systems to verify product quality, detect contamination, and ensure compliance with increasingly stringent safety requirements. These capabilities will be particularly valuable for pharmaceutical, food, and medical device packaging applications where product integrity is paramount.

The future of packaging automation promises manufacturing operations that are more efficient, flexible, and sustainable than ever before, while creating new opportunities for companies to differentiate themselves through superior packaging capabilities and customer service.