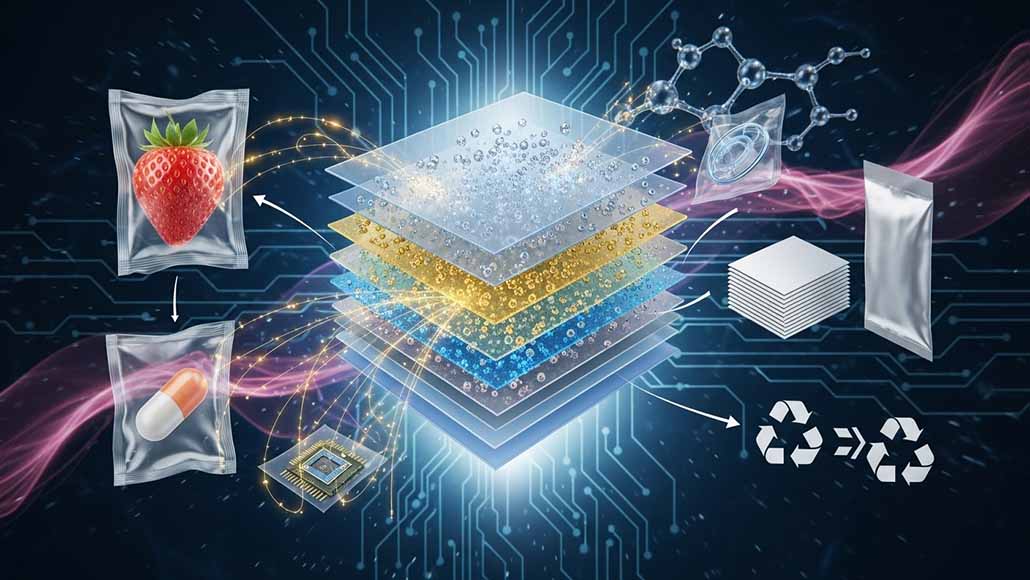

Barrier packaging has always been a cornerstone of product protection in the packaging sector. As industries ranging from food and beverages to pharmaceuticals evolve, so does the need for more advanced materials that not only preserve product integrity but also align with shifting environmental expectations. This is where nanotechnology in barrier packaging is making a marked impact. The integration of nanoscale materials into barrier layers is redefining performance benchmarks, offering exceptional resistance against moisture, oxygen, and other contaminants—while also opening new frontiers in lightweighting, shelf-life extension, and recyclability.

Nanotechnology’s role in packaging is firmly grounded in practicality. When applied to barrier films, nanomaterials such as nanoclays, nano-silica, or graphene derivatives are used in ultra-thin layers to dramatically reduce permeability. These invisible enhancements result in packages that are more compact yet more durable, simultaneously meeting logistical efficiency and product safety requirements. For packaging professionals, procurement heads, and sustainability officers, this science-backed evolution offers real-world solutions without compromising on cost or compliance.

Key Benefits of Nanotechnology in Barrier Packaging

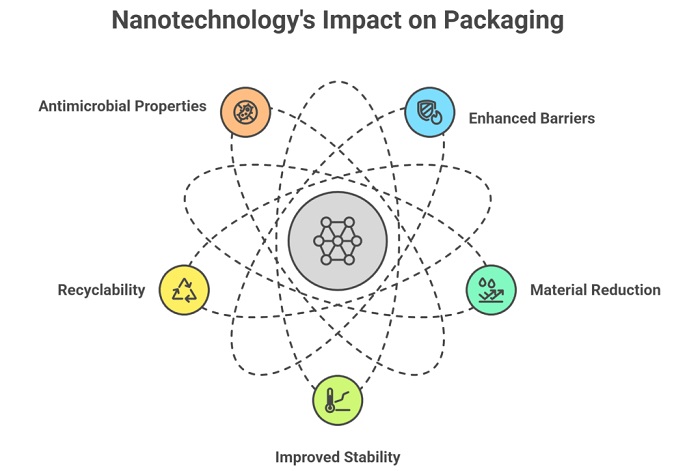

- Enhanced oxygen and moisture barriers: Nanocoatings and nanocomposites significantly limit gas and vapour transmission, which is crucial for preserving perishable goods and extending shelf life.

- Material reduction with better performance: The strength of nanomaterials enables thinner films to provide the same or even improved levels of protection, reducing the amount of raw material used.

- Improved thermal and mechanical stability: Packaging infused with nanoscale elements exhibits better resistance to heat, pressure, and mechanical wear, allowing for greater versatility across product categories.

- Compatibility with recyclability goals: Certain nanotechnologies are designed to be incorporated within mono-material structures, supporting circular economy models by simplifying sorting and recycling processes.

- Antimicrobial potential: Some nanoparticle additives, such as nano-silver or zinc oxide, can provide added antimicrobial properties, particularly relevant in pharmaceutical and fresh produce applications.

Performance, Regulation, and Emerging Hybrids

In the realm of nanotechnology in barrier packaging, much of the current innovation is inspired by the complex challenges of balancing product preservation with environmental responsibilities. For instance, in the food industry, oxidation remains one of the primary culprits behind spoilage. Conventional multilayer plastics have long addressed this issue, but they often create recycling bottlenecks. Nanotechnology offers an alternative by enhancing barrier capabilities using fewer layers and more recyclable substrates.

Pharmaceutical packaging too is seeing a strategic shift. The need to protect sensitive drugs from humidity and UV radiation has typically led to the use of complex foil-based laminates. Nanotechnology is enabling the development of lighter, more flexible alternatives that still deliver the same level of impermeability. A recent study also highlighted how layered silicate nanoclays embedded in polymer matrices helped reduce both oxygen and water vapour permeability in blister packs and sachets while also improving their tensile strength.

From a supply chain perspective, nanotechnology allows for more efficient palletisation and warehousing. Lightweight but high-barrier materials reduce load stress, cut shipping costs, and enable extended distribution networks without product degradation. For exporters, especially those dealing in moisture-sensitive commodities, these innovations can translate into fewer returns, less spoilage, and tighter compliance with international regulations.

Another area where nanotechnology in barrier packaging is making strides is in its contribution to lifecycle sustainability. As Extended Producer Responsibility (EPR) laws and packaging waste directives tighten globally, there is growing demand for packaging materials that meet both performance and environmental criteria. Nano-enhanced mono-materials are showing potential here, particularly when used in polyethylene-based structures. These are easier to process in existing recycling streams, offering a path to both higher recyclability and lower material use.

At the intersection of innovation and regulation, standardisation is emerging to support the responsible use of nanomaterials in packaging. Organisations like the International Organization for Standardization (ISO) and the European Committee for Standardization (CEN) are actively developing technical specifications and testing protocols for nanomaterials in packaging, ensuring their safe deployment and consumer confidence.

Hybrid Innovations: Pairing Nano with Renewable Materials

It is worth noting that nanotechnology in barrier packaging does not stand in isolation but complements other material science advancements. For instance, pairing nanocomposites with bio-based films or integrating nanocoatings into paper substrates is being explored as a strategy to create next-generation barrier solutions with reduced carbon footprints. These hybrid approaches blend the strengths of renewable resources with the impermeability benefits of nano-engineering, pointing toward a more resilient and resource-efficient packaging future.

In the business landscape, this translates into tangible value. Packaging manufacturers can offer brand owners more versatile formats. Retailers benefit from reduced wastage and improved on-shelf product stability. Logistics providers see advantages in reduced breakage and fewer temperature-sensitive constraints. Procurement leaders, on the other hand, can more confidently choose materials that meet cross-sectoral requirements—be it food-grade, pharma-compliant, or export-friendly—without having to trade off performance for sustainability.

Conclusion

Looking ahead, the trajectory of nanotechnology in barrier packaging suggests even greater integration with smart packaging systems. Researchers are exploring nanosensors that could be embedded into films to monitor freshness, detect contamination, or even trigger alerts on spoilage—all in real time. While still largely in developmental stages, these capabilities hint at a future where barrier films will not only preserve but also communicate.

In conclusion, the convergence of nanotechnology and packaging science is fostering a new era of performance, precision, and sustainability in material design. As global industries navigate complex consumer demands and regulatory frameworks, nanotechnology in barrier packaging emerges not just as an innovation but as a strategic enabler. For the packaging ecosystem, from converters and material suppliers to brand owners and compliance teams, it provides a toolkit of possibilities that are practical, scalable, and future-ready. The silent strength of nanoscale science may well be the most consequential development in packaging since the advent of flexible films, and its influence is only just beginning to unfold.