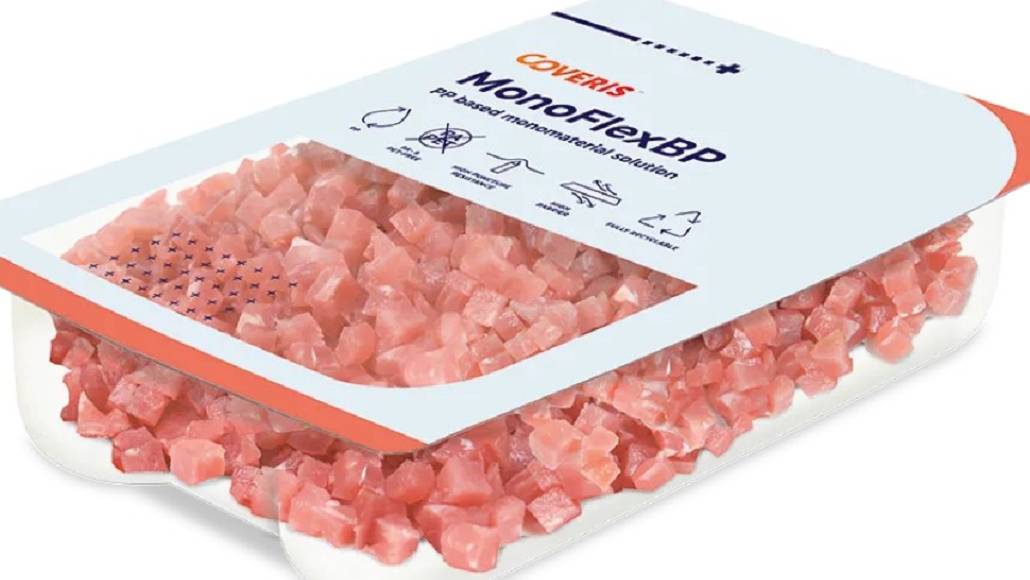

As part of its No Waste initiative, Coveris recently introduced a new resealable monomaterial food packaging solution specifically for refrigerated food products. The company’s latest development, known as the MonoFlexBP tray for refrigerated foods, replaces traditional mixed-material packaging that cannot be recycled, while at the same time ensuring an extended shelf life and delivering higher levels of convenience to consumers.

Fresh and perishable products require packaging formats that protect quality while enabling reclosure once opened. The MonoFlexBP tray for refrigerated foods addresses this challenge with a resealing system that allows the tray to be closed and reopened several times, a feature that helps cut down on food waste while improving usability. Complementing this solution, Coveris also offers thermoformable bottom films that provide strong product protection, thereby helping to preserve freshness across a wide variety of chilled categories.

For applications where oxygen barriers are a critical requirement, the company has introduced a PET- and PA-free lidding film that seals, peels, and reseals effectively on PP trays. This resealable lidding option incorporates a robust gas barrier, a vital element in maintaining freshness for perishable goods. Together, the recyclable MonoFlexBP trays and reclosable lidding films create a solution that combines packaging performance with sustainability and user-focused functionality.

“We are extremely pleased to launch MonoFlexBP tray for refrigerated goods. With this sustainable alternative to non-recyclable materials, Coveris continues to lead the way in circular packaging innovation, offering high-performance solutions that address both environmental impact and consumer demand”, said Katja Killian, BU Flexibles Business Development Director at Coveris.

The MonoFlexBP refrigerated food tray provides good sealability while providing consistent resealability for repetitive use. Its user-friendly opening and reclosure feature enhances daily convenience and reduces food wastage by maintaining the freshness of the product for longer durations.

Being a completely recyclable monomaterial food packaging solution, the tray ensures commitment to the environment without harming the strength or performance of the tray. It is compatible to fit with the existing equipment, which ensures seamless integration for food manufacturers.

The solution is appropriate for processed meats, sausages, dairy, cheeses, and other chilled ranges. Designs include a high gas barrier for increased protection, as well as surface finishes such as matte or paper-effect lacquer. For branding, the trays also can be printed using gravure or flexographic techniques.