How Kraft Packaging is Evolving: Durability, Design & Sustainability

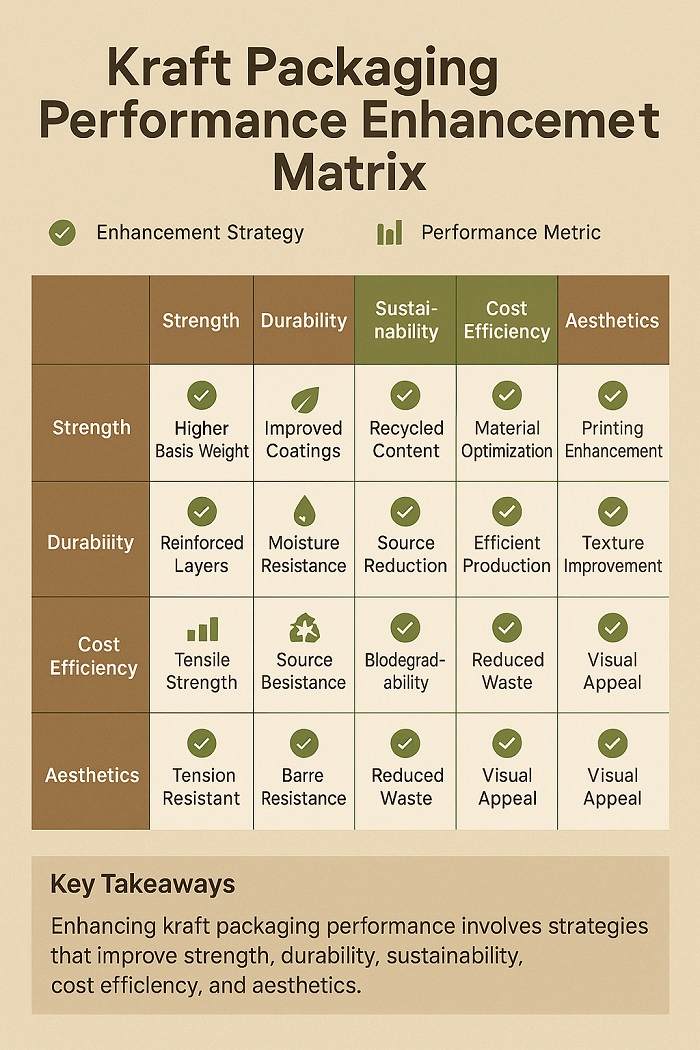

The renaissance of kraft packaging represents one of the most significant material evolution stories in modern packaging, transforming a century-old brown paper solution into a sophisticated, high-performance packaging system that meets contemporary demands for durability, aesthetic appeal, and environmental responsibility. Kraft packaging innovations have redefined industry perceptions while creating new market opportunities across diverse application sectors.

The Scientific Foundation of Modern Kraft Innovation

Contemporary kraft packaging innovations build upon the fundamental strength characteristics that made kraft paper valuable since Carl F. Dahl’s original process development in the 1880s. The kraft process strips lignin from wood pulp while preserving cellulose fibers, creating inherently strong materials that form the foundation for advanced packaging solutions.

Modern kraft manufacturing incorporates sustainable forestry practices, closed-loop water systems, and renewable energy utilization that minimize environmental impact while maximizing resource efficiency. The global kraft paper market, valued at $17.09 billion in 2022 and projected to reach $21.6 billion by 2029, reflects growing recognition of kraft’s unique combination of performance and sustainability benefits.

Advanced kraft formulations utilize varying fiber lengths, pulping techniques, and processing parameters to optimize specific performance characteristics including tensile strength, burst resistance, moisture tolerance, and printability. These engineered approaches enable kraft packaging to compete effectively with synthetic alternatives across demanding application requirements.

Chemical additives and coating systems enhance kraft packaging performance without compromising biodegradability or recyclability. Natural wax coatings, plant-based barriers, and bio-derived adhesives provide enhanced protection while maintaining environmental credentials that differentiate kraft solutions from petroleum-based alternatives.

Durability Enhancements Through Engineering Excellence

Kraft packaging innovations achieve remarkable durability improvements through structural design optimization, material engineering, and manufacturing process refinement that create packaging solutions capable of withstanding demanding transportation and handling conditions. Multi-layered kraft constructions combine different paper grades to optimize strength, flexibility, and barrier properties for specific application requirements.

Corrugated kraft packaging represents the most significant durability advancement, utilizing fluted mediums between kraft liners to create lightweight structures with exceptional compression and edge crush strength. These engineered configurations provide superior protection while minimizing material usage and transportation costs compared to solid paperboard alternatives.

Reinforcement techniques including edge banding, corner protection, and structural ribbing enhance kraft packaging durability without requiring additional materials or synthetic components. These design innovations distribute stress loads efficiently while maintaining the natural appearance and environmental benefits that characterize premium kraft packaging solutions.

Testing and validation protocols ensure kraft packaging innovations meet or exceed performance requirements for specific applications, utilizing standardized methods including burst testing, compression analysis, and environmental exposure evaluation. These rigorous testing approaches provide confidence in kraft packaging performance while identifying opportunities for further optimization.

Design Revolution and Aesthetic Innovation

The transformation of kraft packaging from utilitarian brown containers to sophisticated design platforms demonstrates how material innovation can enhance both functionality and aesthetic appeal. Contemporary kraft packaging incorporates advanced printing technologies, finishing techniques, and structural design elements that create premium brand experiences while maintaining authentic, natural characteristics.

Digital printing capabilities specifically optimized for kraft substrates enable high-quality graphics reproduction, precise color registration, and variable data printing that creates personalized packaging experiences. These technological advances eliminate traditional limitations of kraft printing while expanding creative possibilities for brand communication and customer engagement.

Finishing innovations including embossing, debossing, die-cutting, and foil stamping create textural and visual interest that enhances perceived value while reinforcing premium positioning. These finishing techniques prove particularly effective on kraft substrates due to the material’s natural texture and authentic appearance that complements sophisticated finishing applications.

Color innovation extends beyond traditional brown kraft through bleaching processes and natural dyeing techniques that create diverse color palettes while preserving environmental benefits. White kraft, colored kraft, and specialty finishes expand design possibilities while maintaining the strength and sustainability characteristics that define premium kraft packaging.

Minimalist design approaches leverage kraft’s natural aesthetic to create sophisticated packaging solutions that communicate authenticity, environmental responsibility, and premium quality through understated elegance rather than elaborate graphics or finishing techniques.

Sustainability Leadership and Environmental Innovation

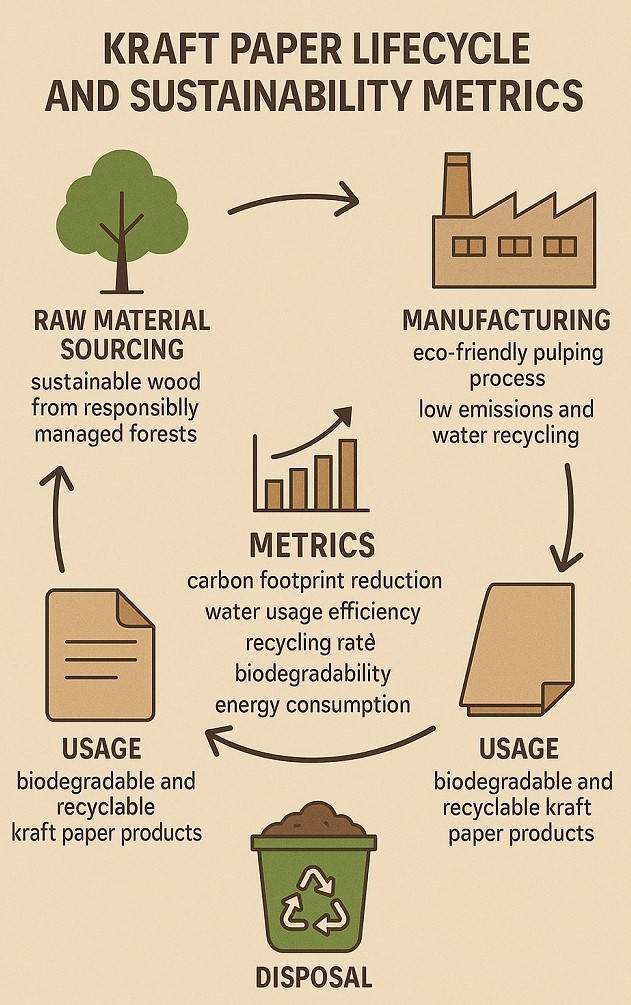

Kraft packaging innovations consistently demonstrate superior environmental performance across multiple sustainability metrics including renewable sourcing, carbon footprint, biodegradability, and recyclability. These environmental advantages create competitive differentiation while meeting increasing consumer and regulatory demands for sustainable packaging alternatives.

Forest Stewardship Council certification and Programme for the Endorsement of Forest Certification validation provide third-party verification of sustainable sourcing practices that ensure kraft packaging originates from responsibly managed forests. These certifications enhance consumer confidence while supporting premium pricing strategies based on verified environmental benefits.

Carbon footprint optimization through renewable energy utilization, transportation efficiency improvements, and manufacturing process optimization reduces greenhouse gas emissions associated with kraft packaging production. Life cycle assessment studies consistently demonstrate kraft packaging’s superior environmental profile compared to plastic alternatives across multiple impact categories.

Biodegradability characteristics enable kraft packaging to decompose naturally in appropriate composting environments without leaving harmful residues or contributing to persistent pollution problems. This end-of-life advantage proves particularly valuable for single-use applications where disposal considerations influence material selection decisions.

Recycling compatibility ensures kraft packaging integrates seamlessly with existing paper recycling infrastructure while contributing to circular economy objectives. High recycling rates exceeding 87 percent for paper-based packaging demonstrate kraft’s superior performance compared to alternative materials in creating sustainable material loops.

Application Expansion and Market Diversification

Kraft packaging innovations enable application expansion into previously inaccessible market segments through enhanced performance characteristics, design capabilities, and cost optimization that create competitive advantages over traditional materials. Food packaging applications benefit from kraft’s food-safe properties, grease resistance, and natural barrier characteristics that protect products while maintaining sustainability credentials.

E-commerce packaging represents a rapidly growing market segment where kraft packaging innovations excel through optimized strength-to-weight ratios, shipping efficiency, and customer experience enhancement. The natural appearance and premium feel of kraft packaging create positive unboxing experiences that support brand differentiation and customer loyalty in competitive digital commerce environments.

Industrial packaging applications increasingly utilize kraft solutions for business-to-business shipments where durability, cost-effectiveness, and environmental responsibility create value across extended supply chains. Heavy-duty kraft constructions replace wooden packaging, metal containers, and plastic solutions while providing comparable protection at reduced environmental cost.

Luxury goods packaging leverages kraft’s natural aesthetic and premium finishing capabilities to create sophisticated packaging experiences that align with high-value product positioning. The contrast between kraft’s authentic appearance and luxury finishing techniques creates memorable brand experiences that justify premium pricing while supporting environmental messaging.

Technology Integration and Smart Packaging Features

Kraft packaging innovations increasingly incorporate digital technologies and smart features that enhance functionality while maintaining environmental benefits and natural aesthetic characteristics. Quick response codes, near field communication tags, and augmented reality applications integrated into kraft packaging create interactive customer experiences without compromising material recyclability.

Sensor integration enables kraft packaging to monitor environmental conditions, track shipping status, and provide authentication capabilities that add value for both brands and consumers. These smart features prove particularly valuable for premium products where authenticity verification and condition monitoring justify additional technology costs.

Blockchain integration provides transparent supply chain tracking and sustainability verification that supports premium pricing while building consumer confidence in environmental claims. Immutable records of sourcing practices, manufacturing processes, and transportation activities create accountability while supporting sustainability marketing messages.

Internet-of-Things connectivity enables kraft packaging to communicate with supply chain management systems, inventory tracking applications, and customer engagement platforms that optimize operational efficiency while enhancing customer service capabilities.

Manufacturing Process Innovation and Efficiency Optimization

Advanced manufacturing techniques optimize kraft packaging production through automation, quality control enhancement, and waste reduction that improve competitiveness while maintaining environmental benefits. Precision manufacturing systems ensure consistent quality while minimizing material waste and energy consumption throughout production processes.

Lean manufacturing principles applied to kraft packaging production eliminate non-value-adding activities while optimizing resource utilization and delivery performance. These efficiency improvements reduce costs while enhancing customer satisfaction through improved quality and service reliability.

Quality management systems utilizing statistical process control, real-time monitoring, and predictive maintenance ensure kraft packaging innovations meet stringent performance requirements while minimizing defects and waste generation. These systems provide confidence in product performance while supporting continuous improvement initiatives.

Flexible manufacturing systems enable economical production of customized kraft packaging solutions in smaller quantities, supporting brand differentiation and market segmentation strategies that create competitive advantages through personalized packaging experiences.

Market Trends and Consumer Response

Consumer acceptance of kraft packaging innovations reflects growing environmental awareness combined with appreciation for authentic, natural aesthetics that differentiate premium products from mass-market alternatives. Market research consistently demonstrates positive consumer associations with kraft packaging across multiple demographic segments and product categories.

Premium positioning strategies utilizing kraft packaging innovations achieve higher perceived value and pricing power through environmental messaging, aesthetic differentiation, and quality associations that justify cost premiums over conventional packaging alternatives. These positioning advantages prove particularly valuable in competitive markets where functional product differences are minimal.

Brand differentiation through kraft packaging enables companies to communicate environmental responsibility, authenticity, and quality values that resonate with contemporary consumer priorities. This messaging proves particularly effective with younger demographic groups who prioritize environmental considerations in purchasing decisions.

Market expansion opportunities continue growing as kraft packaging innovations achieve performance parity with synthetic alternatives while maintaining superior environmental profiles. This performance improvement creates opportunities for market share gains across applications previously dominated by plastic packaging solutions.

Strategic Implications and Future Outlook

The evolution of kraft packaging represents a fundamental shift toward sustainable packaging solutions that meet contemporary performance requirements while addressing environmental concerns. Organizations that invest proactively in kraft packaging innovations position themselves advantageously for sustained growth as regulatory and consumer pressures favor environmentally responsible packaging choices.

Innovation investment priorities focus on continued performance improvement, application expansion, and cost optimization that maintain kraft packaging’s competitive advantages while extending market opportunities. Research and development efforts concentrate on barrier enhancement, strength improvement, and processing optimization that address remaining performance gaps with synthetic alternatives.

Partnership strategies with suppliers, customers, and technology providers accelerate innovation development while distributing risks and costs associated with advanced technology implementation. Collaborative approaches prove particularly valuable for developing specialized solutions that serve niche market requirements while maintaining economies of scale in manufacturing operations.

The trajectory of kraft packaging evolution indicates continued growth and market expansion as environmental regulations tighten, consumer preferences evolve, and technology capabilities advance. Organizations that embrace this evolution while maintaining focus on sustainability, performance, and customer value creation will establish market leadership positions that strengthen as kraft packaging innovations achieve broader market acceptance.