Easy-to-use industrial edge controller for fast and reliable on-site data utilization and visualization

OMRON has announced the launch of the unique DX1 Data Flow Controller, its first industrial edge controller designed to make factory data collection and utilization simple and accessible. Created to seamlessly integrate into OMRON’s Sysmac Automation Platform, the DX1 can collect, analyze, and visualize operation data from sensors, controllers, and other automation devices directly on the factory floor. It enables no-code device configuration, eliminates the need for specialized programs or software, and makes data-driven manufacturing more accessible. This improves Overall Equipment Effectiveness (OEE) and supports transition to IoT.

The DX1 tackles common challenges in data utilization thanks to its ease-of-use and connectivity. Ready-to-use templates and an intuitive flow editor let users quickly create and manage data flows without programming knowledge. At the same time, enhanced compatibility with programmable logic controllers (PLCs) from multiple manufacturers* allows the DX1 to be retrofitted to existing equipment. This seamless integration helps reduce both lead times and initial investment costs for manufacturers.

Advantages of the Data Flow Controller

(1) A quick and easy start to data utilization

The DX1 Data Flow Controller makes data utilization simple and accessible. It is standard equipped with data preparation/analysis middleware (SALTYSTER, Inc.’s SpeeDBee Synapse®). The DX1 allows connecting devices to existing equipment just by hooking them up with Ethernet cables. There is no need to install programs specialized for sensors and controllers required for data collection.

The DX1 Data Flow Controller makes data utilization simple and accessible. It is standard equipped with data preparation/analysis middleware (SALTYSTER, Inc.’s SpeeDBee Synapse®). The DX1 allows connecting devices to existing equipment just by hooking them up with Ethernet cables. There is no need to install programs specialized for sensors and controllers required for data collection.

The user interface enables at-a-glance understanding of data processing flows, allowing companies to start using their data in no time. Users can intuitively create flows for collecting, analyzing, and sending data by simply connecting processing blocks on screen with lines.

(2) From templates to customization: wide-ranging features for wide-ranging scenarios

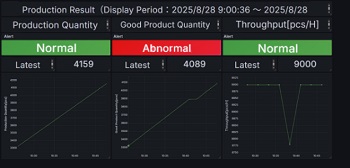

DX1 comes with standard packages that provide templates for key indicator data used in equipment monitoring, operation status monitoring, factory monitoring, and more. Data can be displayed in a tiered structure to suit the needs of a wide range of users, from factory managers to on-site workers, allowing them to drill down from the factory’s production plan targets to equipment operation status. DX1 can also be customized for your site environment using PythonTM and C, to enable connection with controllers from other manufacturers or for complex calculations.

(3) Zero-downtime implementation

OMRON’s new DX1 supports programmable logic controllers (PLCs) from multiple manufacturers. This allows data collection to begin while equipment continues running, with no need for device or software replacement, even when using non-OMRON PLCs. It can also be retrofitted to existing equipment without requiring production to stop for data collection. With the IO-Link master, information devices can be easily connected, enabling direct retrieval of data from different sensors and cameras.