The Engineering Excellence of Nano-Coatings in Flexible Packaging Systems

The global packaging industry is currently undergoing a profound and necessary shift, driven by the intense dual demands of superior product protection and environmental responsibility. At the very center of this massive transformation is the application of nano-coatings in flexible packaging, a technology that operates at the precise intersection of chemistry, physics, and material engineering to solve some of the most persistent challenges in modern manufacturing. Flexible packaging has long been favored by brands for its lightweight nature, cost-effectiveness, and low shipping volumes, but it has traditionally struggled to provide the same level of atmospheric and moisture barrier protection as rigid plastic containers, glass, or aluminum foils. The introduction of nano-coatings has effectively and elegantly bridged this gap, allowing thin, single-layer plastic films to exhibit barrier properties that were previously thought physically impossible for such lightweight and flexible materials.

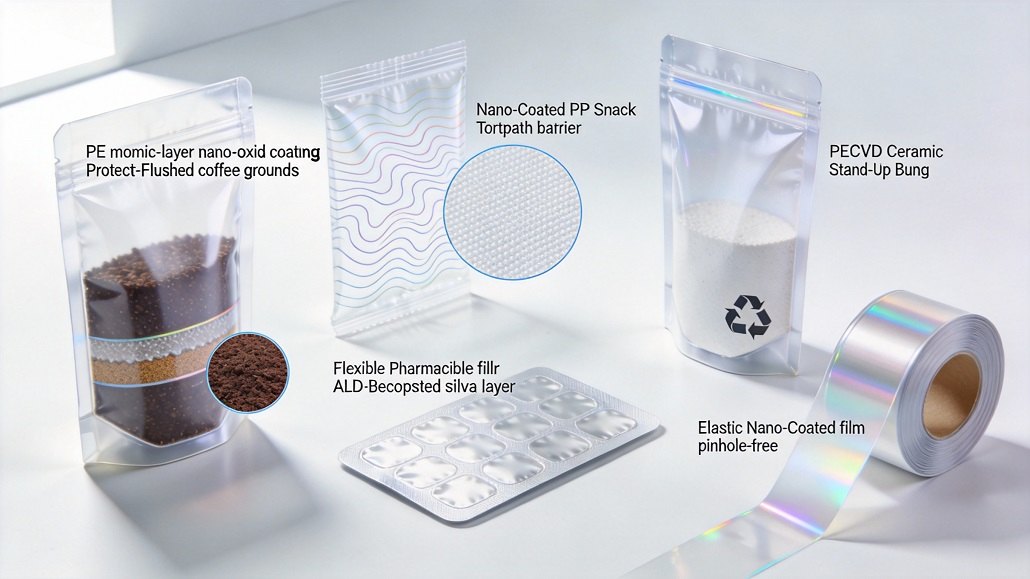

Technological Advancements in Atomic-Scale Coatings

The incredible efficacy of nano-coatings in flexible packaging is rooted in the extreme precision of their application methods. Modern techniques such as Atomic Layer Deposition (ALD) and Plasma-Enhanced Chemical Vapor Deposition (PECVD) allow manufacturers to apply specialized ceramic or metallic oxides in uniform layers that are only a few nanometers thick. To put this in perspective, these layers are thousands of times thinner than a human hair. Because they are so incredibly thin, they do not affect the transparency, flexibility, or “hand-feel” of the base film, yet they provide what is known as a “tortuous path” for gas and water molecules. For a manufacturer, this means that a standard, low-cost polyethylene (PE) or polypropylene (PP) film can be transformed into a high-performance barrier material without significantly increasing the weight, volume, or complexity of the package. This microscopic intervention results in a massive macroscopic benefit: the total isolation of the product from the degrading effects of oxygen, light, and humidity.

Revolutionizing Moisture and Oxygen Resistance in Plastics

The primary metric for success and the ultimate goal in flexible packaging barrier performance is the achievement of a low Water Vapor Transmission Rate (WVTR) and an even lower Oxygen Transmission Rate (OTR). Traditional methods of improving these critical metrics involved creating complex, multi-layer laminates that often included layers of nylon, EVOH, or aluminum foil. While these “multi-material” structures are effective at protection, they are notoriously difficult and expensive to recycle because the different materials cannot be easily or economically separated during the recycling process. Nano-coatings in flexible packaging offer a much more elegant and sustainable solution. By applying a single nano-layer of aluminum oxide or transparent silica, engineers can achieve OTR values that directly rival traditional foil-based structures. This ensures that sensitive products, ranging from nitrogen-flushed snack foods to specialized medical devices and pharmaceuticals, remain in pristine, “factory-fresh” condition throughout their intended shelf life, regardless of the external environmental fluctuations they encounter during global shipping.

Durability and Mechanical Integrity in Global Supply Chains

Beyond their role as gas barriers, advanced packaging coatings also significantly enhance the physical durability and mechanical integrity of the film. Flexible packages are often subjected to significant mechanical stress during the high-speed filling process, shipping, handling, and consumer use. Traditional barrier layers, especially those made of brittle materials, can develop microscopic “pinholes” or cracks when flexed or folded, which immediately compromises the integrity of the internal vacuum or modified atmosphere. Modern nano-coatings are specifically engineered to be highly elastic and resilient, maintaining their continuous barrier performance even after the package has been crushed, twisted, or folded multiple times. This mechanical robustness ensures that the protection remains consistent and reliable from the factory floor to the consumer’s pantry, dramatically reducing the risk of premature spoilage, product returns, and the associated financial losses.

Strategic Implications for Sustainability and Mono-Materials

Perhaps the most significant and strategically important advantage of nano-coatings in flexible packaging is their role in enabling the global circular economy. The intense push to eliminate non-recyclable multi-layer plastics has put immense pressure on global brands to move toward mono-material structures packages made from a single type of plastic. Historically, mono-materials like pure PE lacked the barrier performance required for many shelf-stable food products. Nano-coatings change this equation entirely. Because the coating is so incredibly thin (often representing significantly less than 1% of the total package weight), it does not interfere with the traditional recycling stream of the base polymer. This allow brands to create fully recyclable, high-barrier pouches and films that meet both stringent regulatory requirements and growing consumer expectations for eco-friendly, sustainable packaging. It is a technological “win-win” that removes the traditional trade-off between performance and planet.

Economic Efficiency and Manufacturing Throughput

From a production and operational standpoint, the adoption of moisture barrier materials at the nano-scale offers clear and measurable economic advantages. While the initial investment in specialized vapor deposition or coating equipment can be significant, the long-term savings in raw material costs are substantial. By reducing the number of layers in a complex laminate, manufacturers can lower their total raw material consumption and reduce the energy required for the multi-stage lamination process. Furthermore, high-performance packaging films that utilize nano-coatings are often more compatible with high-speed automated filling and sealing machines, as they are less prone to the “curl,” static build-up, and heat-transfer issues often associated with thicker, more complex multi-layer laminates. This increase in operational efficiency and machine uptime directly translates to higher margins and a much faster time-to-market for new, innovative products.

The Future Horizon: Bio-Based and Active Nano-Coatings

As we look toward the next generation of packaging science, the focus is rapidly shifting toward bio-based and compostable nano-coatings. Researchers are currently developing advanced coatings derived from cellulose, chitin (from shellfish waste), and other natural polymers that provide the same level of protection as their mineral-based counterparts. These innovations will allow for the creation of 100% biodegradable and compostable flexible packaging that can perform at the highest industrial standards for shelf life. Furthermore, the future of nano-coatings in flexible packaging includes “active” functions, where the coating can actively scavenge oxygen or release natural antimicrobial agents into the headspace of the package to further extend freshness. The integration of nanotechnology with green chemistry represents the ultimate frontier in packaging science a world where the package provides absolute, high-tech protection during its use and leaves no trace on the planet once its purpose is fulfilled.

The Role of Nano-Coatings in Pharmaceutical Safety

In the pharmaceutical sector, the importance of a perfect moisture barrier cannot be overstated. Many modern drugs are highly hygroscopic, meaning they absorb moisture from the air, which can lead to chemical degradation and a loss of potency. Nano-coatings provide a way to create blister packs and pouches that are more resistant to moisture ingress than ever before, even in tropical climates with high humidity. This ensures that patients receive the full intended dose of their medication, regardless of where they live. Additionally, these coatings can be engineered to be opaque to specific wavelengths of light, protecting light-sensitive compounds without the need for thick, heavy secondary packaging. This precision in protection is why nano-coatings are quickly becoming a standard requirement for the next generation of pharmaceutical packaging.

Conclusion: A New Standard for Flexible Packaging

In conclusion, nano-coatings are not just a minor addition to the packaging toolkit; they are a fundamental building block of the future of global commerce. By enabling the creation of materials that are at once lighter, stronger, and more protective, nanotechnology is allowing the industry to meet the complex demands of the 21st century. As we continue to refine these molecular tools and integrate them with sustainable materials, the standard for what a “good” package looks like will continue to rise. Nano-coatings in flexible packaging have proven that the best things really do come in small packages or rather, in very thin layers. The future of packaging is clear, flexible, and molecularly engineered for a safer and more sustainable world.