In today’s changing industrial scenario, the packaging industry finds itself at the juncture of technology and process perfection. The demand for faster production cycles, reduced waste, and better supply chain synchronisation has never been so acute. As a means to address these needs, businesses are going in for ERP integration in packaging in large numbers to transform their workflows. By connecting all processes—from production and inventory to logistics and compliance—ERP integration in packaging is redefining what it means to operate efficiently and collaboratively in the modern era.

What Is ERP?

Enterprise Resource Planning (ERP) software is meant to bring together and streamline business operations. In the packaging business, ERP integration is a scenario where all functions—inventory control, procurement, production planning, and shipment—are integrated. Packaging, previously managed as a standalone operation, is integrated into the bigger picture of enterprise function. End-to-end, it enables organisations to operate as single, responsive units rather than as aggregates of conflicting departments.

The U.S. Bureau of Labour Statistics notes that manufacturing, which includes packaging, employs millions and is the central sector of the U.S. economy. As those industries transition into digital, ERP systems are increasingly seen as a core infrastructure to stay competitive and agile.

Streamlining Workflow Efficiency with Smooth Integration

Workflow efficiency is the cornerstone of operational excellence in packaging. Paper-based, manual systems can create bottlenecks, delays, and unnecessary duplication. ERP integration in packaging substitutes these roadblocks with electronic workflows that electronically share data and synchronise departmental activities.

For instance, when packaging requirements are updated, the ERP system automatically communicates these changes to relevant departments. This communication avoids email or phone call exchanges, allowing teams to focus on value-adding activities.

Increasing Coordination Down the Supply Chain

Efficient communication and coordination are the cornerstones of modern package operations. ERP integration with packaging places all departments on common ground. Upon sales committing an order, the information immediately alerts procurement, inventory, and manufacturing groups, preparing materials and making schedules aligned. Logistics partners get notified in real-time when products are ready to go out, maintaining lead times at a bare minimum and maximising transportation assets.

The United Nations Industrial Development Organization (UNIDO) explains that integrated management systems encourage greater supply chain transparency and responsiveness, both of which are key to firms that need to meet deadlines and rapidly change their response to changing customers’ requirements.

Driving Better Decision-Making with Real-Time Insights

ERP integration with packaging doesn’t only optimise day-to-day functioning—it makes informed, strategic decisions with real-time visibility possible. The analytics capabilities embedded in ERP systems provide a bird’s-eye view of key metrics, ranging from production levels to inventory turnover rates. The knowledge helps the managers to spot inefficiencies at once, optimise resource allocation, and plan for future growth.

The Organisation for Economic Co-operation and Development (OECD) states that businesses that use digital technology such as ERP systems are in a good position to make informed decisions through data and continuous improvement. In packaging, this could mean being able to forecast market trends, reduce wastage, and have reasonable costs.

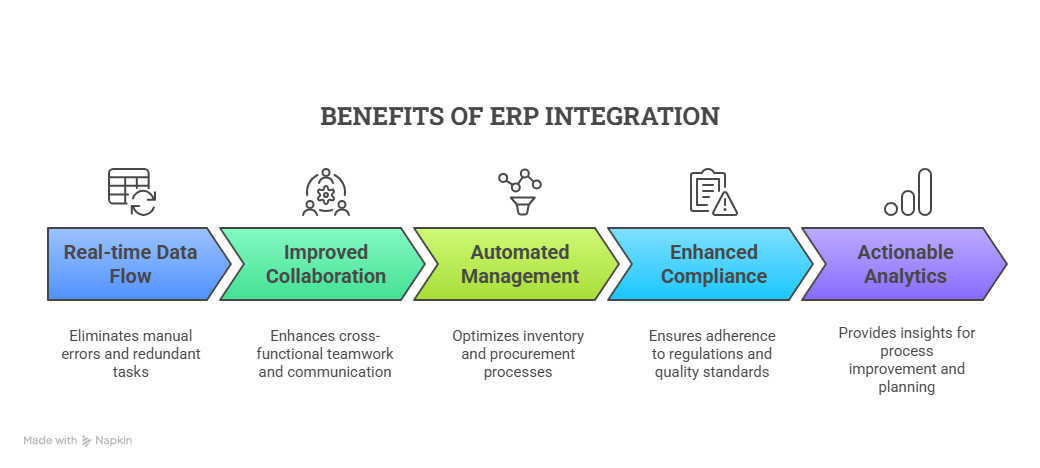

Major advantages of ERP integration in packaging

- Real-time data flow eliminates manual errors and redundant tasks.

- Improved cross-functional collaboration and communication.

- Automated inventory and procurement management for optimal resource use.

- Enhanced compliance and quality control, especially in regulated sectors.

- Actionable analytics for continuous process improvement and strategic planning.

Looking Ahead

With the packaging industry evolving, ERP integration is leading the way to even smarter, more integrated processes. Government agencies such as the U.S. Department of Commerce and UNIDO see the growing use of digital systems in manufacturing. Advances in automation and real-time analysis will only increase the importance of ERP integration, allowing the packaging industry to respond faster to market demand and policy changes.

The next wave of innovation will most likely be in the form of ERP systems running alongside such emerging technologies as IoT and machine learning. This will bring emerging opportunities for predictive maintenance, precise demand forecasting, and even more agile supply chain management.

Conclusion

ERP integration in packaging is not just an efficiency gain—it’s a strategic step that prepares organisations to operate with increased coordination, accuracy, and visibility. Through the embedding of all stages of the workflow together in harmony, ERP systems provide the foundations for operational excellence and sustained growth. With the packaging industry embracing this era of digital transformation, those on the bandwagon of ERP packaging integration will be at the forefront—set to face the challenges and possibilities of a rapidly changing world.