The convergence of digital technologies, advanced manufacturing systems, and interconnected industrial networks has ushered in a new era for packaging operations worldwide. Industry 4.0 in packaging represents a fundamental shift from traditional manufacturing approaches to intelligent, data-driven production environments that respond dynamically to market demands while optimizing efficiency, quality, and sustainability. This transformation extends beyond simple automation to encompass comprehensive digitalization of packaging processes, creating smart factories that operate with unprecedented sophistication and adaptability.

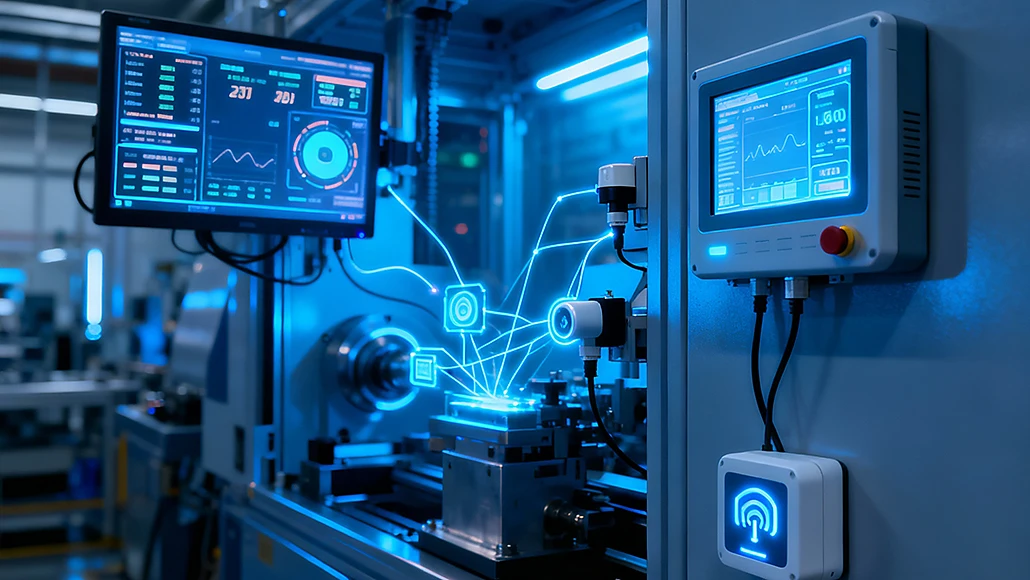

Modern packaging facilities are evolving into interconnected ecosystems where every component communicates, analyzes, and optimizes performance in real-time. This digital transformation encompasses everything from individual sensors monitoring packaging line performance to enterprise-wide systems that coordinate production schedules with supply chain logistics and customer requirements. The result is manufacturing operations that achieve levels of efficiency, flexibility, and quality that were previously impossible with conventional approaches.

Connected packaging systems enable manufacturers to create seamless integration between production planning, execution, and performance monitoring. These systems provide comprehensive visibility into every aspect of packaging operations while enabling rapid response to changing conditions, quality issues, or customer requirements. The strategic value of this connectivity extends throughout the entire value chain, creating opportunities for improved customer service, reduced waste, and enhanced competitive positioning.

Smart Factory Implementation Revolutionizing Operations

The implementation of smart factory concepts in packaging operations creates manufacturing environments where physical systems integrate seamlessly with digital technologies to optimize performance continuously. These facilities leverage advanced sensor networks, machine learning algorithms, and real-time data analytics to create self-optimizing production systems that improve performance over time.

Manufacturing execution systems within smart packaging factories provide comprehensive orchestration of production activities, coordinating equipment operation, material flows, and quality control processes. These systems maintain real-time awareness of production status, enabling immediate response to changing conditions while ensuring optimal resource utilization and quality standards.

Digital twin technologies create virtual representations of packaging equipment and processes, enabling manufacturers to simulate operations, predict performance, and optimize configurations before implementing changes on actual production lines[40]. These virtual models incorporate real-time data from physical systems, creating dynamic representations that evolve alongside actual equipment performance.

Artificial intelligence integration enables smart factories to make autonomous decisions about production optimization, quality management, and maintenance scheduling. Machine learning algorithms analyze historical performance data to identify patterns and predict optimal operating parameters for different products and conditions. This intelligence extends to predictive maintenance programs that prevent equipment failures while minimizing maintenance costs.

Flexible manufacturing systems within smart packaging factories can adapt rapidly to changing product requirements, switching between different packaging formats with minimal downtime. Modular equipment designs combined with intelligent control systems enable manufacturers to reconfigure production lines quickly to accommodate new products or changing market demands.

Advanced quality management systems integrate seamlessly with smart factory operations, providing real-time monitoring of packaging quality parameters while automatically adjusting processes to maintain specifications. Vision systems, sensor networks, and data analytics combine to create quality control capabilities that exceed human inspection accuracy while maintaining high production speeds.

Real-Time Analytics Driving Packaging Excellence

The implementation of comprehensive real-time analytics systems transforms packaging operations from reactive to proactive management approaches, enabling manufacturers to optimize performance continuously while preventing problems before they impact production. These systems collect, analyze, and act upon data from every aspect of packaging operations, creating unprecedented visibility into production performance and opportunities for improvement.

Production monitoring systems capture data from packaging equipment, environmental sensors, and quality control devices to create comprehensive pictures of operational performance. This information enables managers to identify bottlenecks, optimize resource allocation, and improve overall equipment effectiveness through data-driven decision making.

Predictive analytics capabilities analyze historical performance data to forecast equipment maintenance requirements, predict quality issues, and optimize production schedules based on anticipated demand patterns. These systems enable manufacturers to prevent problems rather than simply responding to them after they occur.

Energy management systems monitor power consumption across packaging operations, identifying opportunities for efficiency improvements while reducing environmental impact. Real-time energy analytics enable manufacturers to optimize production schedules to take advantage of favorable energy rates while minimizing peak demand charges.

Supply chain integration through real-time analytics creates seamless coordination between packaging operations and broader logistics networks. These systems provide visibility into material availability, shipping schedules, and customer requirements, enabling packaging operations to optimize their activities within the broader context of supply chain performance.

Performance benchmarking systems compare actual packaging line performance against theoretical maximums and industry standards, identifying specific opportunities for improvement while tracking progress over time. These analytics enable continuous improvement programs that systematically enhance operational effectiveness.

Data-Driven Decision Making Transforming Management

The availability of comprehensive real-time data from Industry 4.0 packaging systems enables management approaches that base decisions on accurate, current information rather than historical assumptions or intuition. This transformation creates more effective resource allocation, improved strategic planning, and enhanced ability to respond rapidly to changing market conditions.

Operational intelligence systems aggregate data from packaging lines, quality control systems, and maintenance activities to provide managers with comprehensive insights into production performance and improvement opportunities. These systems identify patterns and trends that might not be apparent from individual data sources while providing actionable recommendations for optimization.

Resource optimization algorithms analyze production requirements, equipment capabilities, and material availability to determine optimal production schedules and resource allocation strategies. These systems can automatically adjust production plans based on changing priorities while maintaining optimal efficiency and quality standards.

Quality management systems provide real-time feedback on packaging quality metrics, enabling immediate response to deviations from specifications while identifying root causes of quality issues. Advanced analytics identify correlations between process parameters and quality outcomes, enabling proactive quality management approaches.

Customer responsiveness capabilities enable packaging operations to adapt quickly to changing customer requirements or market conditions. Real-time integration with customer ordering systems and market intelligence enables packaging facilities to prioritize production activities based on current demand patterns and customer urgency.

Cost optimization systems analyze all aspects of packaging operations to identify opportunities for reducing costs while maintaining or improving quality and service levels. These systems consider factors such as material costs, energy consumption, labor requirements, and equipment utilization to recommend optimal operating strategies.

Future Evolution of Industry 4.0 in Packaging

The continued evolution of Industry 4.0 technologies promises even more sophisticated packaging operations that will further transform manufacturing capabilities over the coming years. Emerging technologies and approaches will address current limitations while creating entirely new possibilities for packaging efficiency, quality, and sustainability.

Autonomous packaging systems will evolve beyond current automation capabilities to encompass comprehensive self-management of production operations. These systems will make complex decisions about production optimization, quality management, and maintenance scheduling without human intervention while continuously learning and improving their performance.

Edge computing integration will enable packaging equipment to process data locally, reducing latency and improving response times while reducing dependence on centralized computing resources. This capability will be particularly valuable for applications requiring immediate response to changing conditions or quality issues.

Blockchain integration will create transparent, immutable records of packaging operations, providing comprehensive traceability for regulatory compliance and quality assurance purposes. This technology will enable new business models based on guaranteed packaging performance and quality verification.

Advanced sensor technologies including hyperspectral imaging, chemical sensors, and non-invasive inspection systems will provide unprecedented visibility into product and packaging quality. These sensors will detect issues that are currently impossible to identify while maintaining high production speeds.

Artificial intelligence will evolve to encompass more sophisticated decision-making capabilities, managing complex trade-offs between efficiency, quality, sustainability, and cost objectives. These systems will optimize packaging operations across multiple variables simultaneously while adapting to changing priorities and conditions.

Sustainability optimization will become integral to Industry 4.0 packaging systems, with intelligent systems automatically selecting packaging configurations and operating parameters that minimize environmental impact while meeting performance requirements. These capabilities will enable manufacturers to achieve sustainability objectives without compromising operational effectiveness.

The integration of augmented reality and virtual reality technologies will transform training, maintenance, and troubleshooting activities within smart packaging factories. These technologies will enable remote expertise, accelerated learning, and enhanced problem-solving capabilities while reducing the need for specialized on-site personnel.