Risk Points in Air Cold Chain Logistics: From Tarmac to Last-Mile Transfer

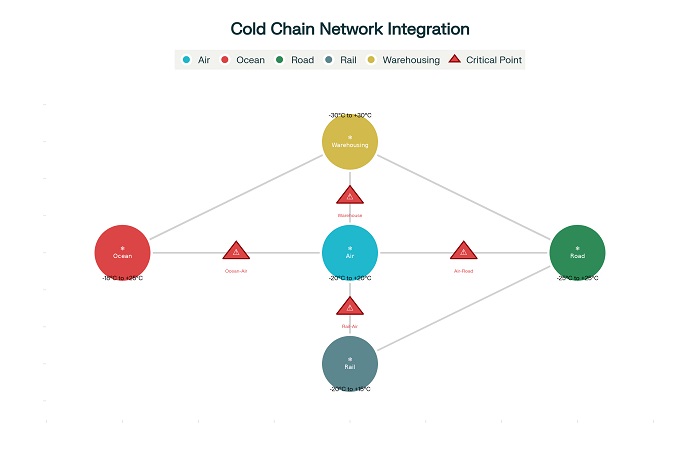

Temperature-sensitive products face numerous vulnerability points throughout their air transportation journey, from initial packaging through final delivery. Each stage of the cold chain presents unique risks that can compromise product integrity, result in financial losses, and potentially endanger public health when pharmaceuticals or biologics are involved. Understanding these risk points and implementing appropriate mitigation strategies is essential for maintaining cold chain integrity in the demanding environment of air cargo operations.

The challenge of managing air cold chain risks extends beyond simple temperature monitoring to encompass timing coordination, equipment reliability, personnel training, and contingency planning across multiple stakeholders and geographic locations. Success requires a systematic approach that identifies potential failure points and implements redundant safeguards to ensure product integrity throughout the transportation process.

Tarmac Exposure and Ground Operations

Perhaps no phase of air cold chain logistics presents greater risk than tarmac operations, where temperature-sensitive cargo faces direct exposure to ambient conditions during loading, unloading, and aircraft servicing activities. Tarmac temperatures can reach extreme levels, with recorded exposures of up to 63°C in some locations during summer months, far exceeding the tolerance limits of most temperature-sensitive products.

The duration of tarmac exposure compounds the temperature risk, as cargo may sit on exposed tarmacs for hours during aircraft turnarounds, maintenance delays, or air traffic control holds. Standard ground handling procedures often prioritize operational efficiency over temperature protection, leading to extended exposure periods that can compromise even well-insulated packaging systems.

Aircraft positioning and scheduling decisions directly impact tarmac exposure risks. Flights scheduled during peak temperature periods or aircraft parked in direct sunlight create more challenging conditions for temperature-sensitive cargo. Ground handling equipment capabilities vary significantly between airports, with some facilities lacking adequate thermal protection equipment or trained personnel.

Weather conditions beyond temperature present additional tarmac risks, including precipitation that can compromise packaging integrity and wind conditions that affect handling procedures. Extreme weather events may cause extended delays that exceed the protective capabilities of passive temperature control systems.

Mitigation strategies for tarmac risks include thermal covers and blankets that provide additional insulation during ground operations. Pre-conditioned packaging systems that begin transportation with thermal mass configured for expected exposure conditions help extend protection periods. Priority handling procedures that minimize ground time for temperature-sensitive cargo require coordination between airlines, ground handlers, and cargo facilities.

Aircraft Cargo Hold Environment

Commercial aircraft cargo holds present a complex environment for temperature-sensitive cargo, with limited climate control capabilities compared to dedicated refrigerated transportation systems. Most passenger aircraft provide only basic temperature management in cargo areas, typically maintaining temperatures between 4°C and 29°C, which may not meet the specific requirements of pharmaceutical or other sensitive products.

Altitude and pressure changes during flight affect both temperature conditions and packaging performance. The low-pressure environment at cruising altitude can cause packaging materials to expand or contract, potentially compromising insulation effectiveness or creating pathways for temperature transfer.

Cargo loading configurations influence temperature distribution within aircraft holds, with cargo positioned near aircraft walls or heating systems facing different thermal conditions than centrally located items. The mixing of temperature-sensitive cargo with general cargo may create thermal challenges that affect product integrity.

Flight duration and routing decisions impact the total time that cargo spends in aircraft environmental conditions. Extended flights or routes with multiple connections increase exposure time and require more robust packaging solutions to maintain temperature integrity.

Loading and Unloading Operations

The transfer of temperature-sensitive cargo between ground vehicles and aircraft represents critical risk points where products face rapid environmental changes and potential handling damage. Loading dock conditions often lack climate control, exposing cargo to ambient temperatures during sorting and preparation activities.

Equipment compatibility issues between different ground handling systems can create delays and additional exposure risks. Specialized handling equipment for temperature-sensitive cargo may not be available at all airports, forcing reliance on standard equipment that provides less thermal protection.

Personnel training and awareness significantly impact loading and unloading risks. Ground handling staff may not understand the urgency and special requirements of temperature-sensitive cargo, leading to inappropriate handling procedures or extended exposure periods.

Documentation and identification systems must clearly communicate temperature requirements and handling instructions to all personnel involved in loading and unloading operations. Poor communication can result in inappropriate treatment of sensitive cargo.

Warehouse and Storage Facility Risks

Cold storage facilities at airports present their own set of risks, despite being specifically designed for temperature-sensitive cargo. Power failures or refrigeration system malfunctions can create temperature excursions that affect large quantities of cargo simultaneously.

Facility temperature mapping and monitoring systems may have blind spots or calibration issues that prevent accurate assessment of storage conditions. Inadequate monitoring can allow temperature excursions to go undetected until product damage occurs.

Cross-contamination risks arise when different types of temperature-sensitive cargo with varying requirements share storage space. Improper segregation can expose products to inappropriate conditions or compromise their integrity through proximity effects.

Inventory management systems must ensure appropriate rotation and minimize storage duration to prevent products from exceeding their cold chain stability limits. Poor inventory control can result in products remaining in storage beyond their recommended time limits.

Customs and Regulatory Processing

Customs clearance procedures present significant risks for temperature-sensitive cargo, as products may spend extended periods in non-controlled environments during inspection and documentation processes. Customs facilities often lack adequate cold storage capabilities, forcing temperature-sensitive cargo to remain in ambient conditions during clearance.

Documentation delays can extend customs processing time beyond the protective capabilities of packaging systems. Incomplete or incorrect paperwork may result in additional inspections or holds that compromise temperature integrity.

Physical inspection requirements for certain products may necessitate opening packaging systems and exposing contents to ambient conditions. These inspections must be conducted quickly and in appropriate environments to minimize temperature impact.

Regulatory approval processes for pharmaceutical products may involve additional delays and handling requirements that create additional risk points. Import permits and special authorizations can take time to process, during which products must maintain temperature integrity.

Last-Mile Delivery Challenges

The final delivery phase presents unique challenges as cargo transitions from specialized air freight infrastructure to local delivery networks that may lack cold chain capabilities. Local courier services often use standard vehicles without temperature control, creating risks during final delivery.

Urban traffic conditions and delivery routing decisions affect the time that temperature-sensitive cargo spends in local delivery vehicles. Extended delivery routes or traffic delays can exceed the protective capabilities of packaging systems designed for rapid final delivery.

Recipient availability and acceptance procedures impact delivery timing and may require products to wait in vehicles or delivery facilities without adequate temperature protection. Coordinating delivery timing with recipient schedules becomes critical for maintaining temperature integrity.

Delivery vehicle capabilities vary significantly between different courier services and geographic regions. Some areas may lack access to refrigerated delivery vehicles or trained personnel capable of handling temperature-sensitive cargo appropriately.

Environmental and Seasonal Factors

Seasonal temperature variations create different risk profiles throughout the year, requiring adaptive strategies that account for changing ambient conditions. Summer operations face heat exposure risks, while winter conditions may present freezing hazards for products with specific temperature ranges.

Geographic routing decisions must consider climate conditions along transportation routes and at destination airports. Some routes may present greater environmental challenges than others, requiring enhanced packaging or alternative routing strategies.

Extreme weather events including storms, temperature extremes, and natural disasters can disrupt normal cold chain operations and create emergency conditions that exceed standard mitigation capabilities. Emergency response procedures must address various weather-related scenarios.

Human Factors and Training Issues

Personnel training and awareness represent critical factors in cold chain risk management, as human error can compromise even the most sophisticated technical systems. Inadequate training may result in improper handling procedures, inappropriate storage conditions, or delayed response to temperature excursions.

Communication failures between different stakeholders can create coordination problems that affect cold chain performance. Clear protocols and communication systems help ensure that all parties understand their responsibilities and timing requirements.

Fatigue and workload pressures may affect personnel performance and attention to detail, particularly during busy periods or extended shifts. Adequate staffing levels and appropriate work procedures help maintain performance standards.

Technology Failures and System Limitations

Temperature monitoring and tracking systems may experience technical failures that prevent accurate assessment of cold chain conditions. Battery failures, communication disruptions, and sensor malfunctions can create blind spots in monitoring coverage.

Packaging system limitations may be exceeded by extreme conditions or extended exposure periods beyond design specifications. Understanding packaging capabilities and limitations helps establish appropriate handling procedures and backup plans.

Integration challenges between different technology systems used by various stakeholders can create information gaps and coordination problems. Compatible systems and standardized protocols help ensure seamless information sharing.

Mitigation Strategies and Best Practices

Successful cold chain risk management requires comprehensive strategies that address all identified risk points through appropriate controls and procedures. Redundant protection systems provide backup capabilities when primary systems fail or encounter extreme conditions.

Proactive monitoring and early warning systems enable rapid response to developing problems before they affect product integrity. Real-time alerts and automated notifications help ensure that problems receive immediate attention.

Continuous improvement processes help identify new risks and develop enhanced mitigation strategies based on operational experience and changing conditions. Regular risk assessments and performance reviews enable ongoing optimization of cold chain procedures.

The complexity of air cold chain logistics requires vigilant attention to numerous risk points throughout the transportation process. Organizations that systematically identify these risks and implement comprehensive mitigation strategies will achieve superior performance while protecting valuable temperature-sensitive cargo from compromise. As cold chain requirements continue evolving and product sensitivity increases, effective risk management will become even more critical for operational success.